Researchers have created a light-powered soft robot that can carry loads through the air along established tracks, similar to cable cars or aerial trams.

The soft robot operates autonomously, can climb slopes at angles of up to 80 degrees, and can carry loads up to 12 times its weight.

“We’ve previously created soft robots that can move quickly through the water and across solid ground, but wanted to explore a design that can carry objects through the air across open space,” says Jie Yin, corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University.

“The simplest way to do this is to follow established an established track—similar to the aerial trams you see in the mountains. And we’ve now demonstrated that this is possible.”

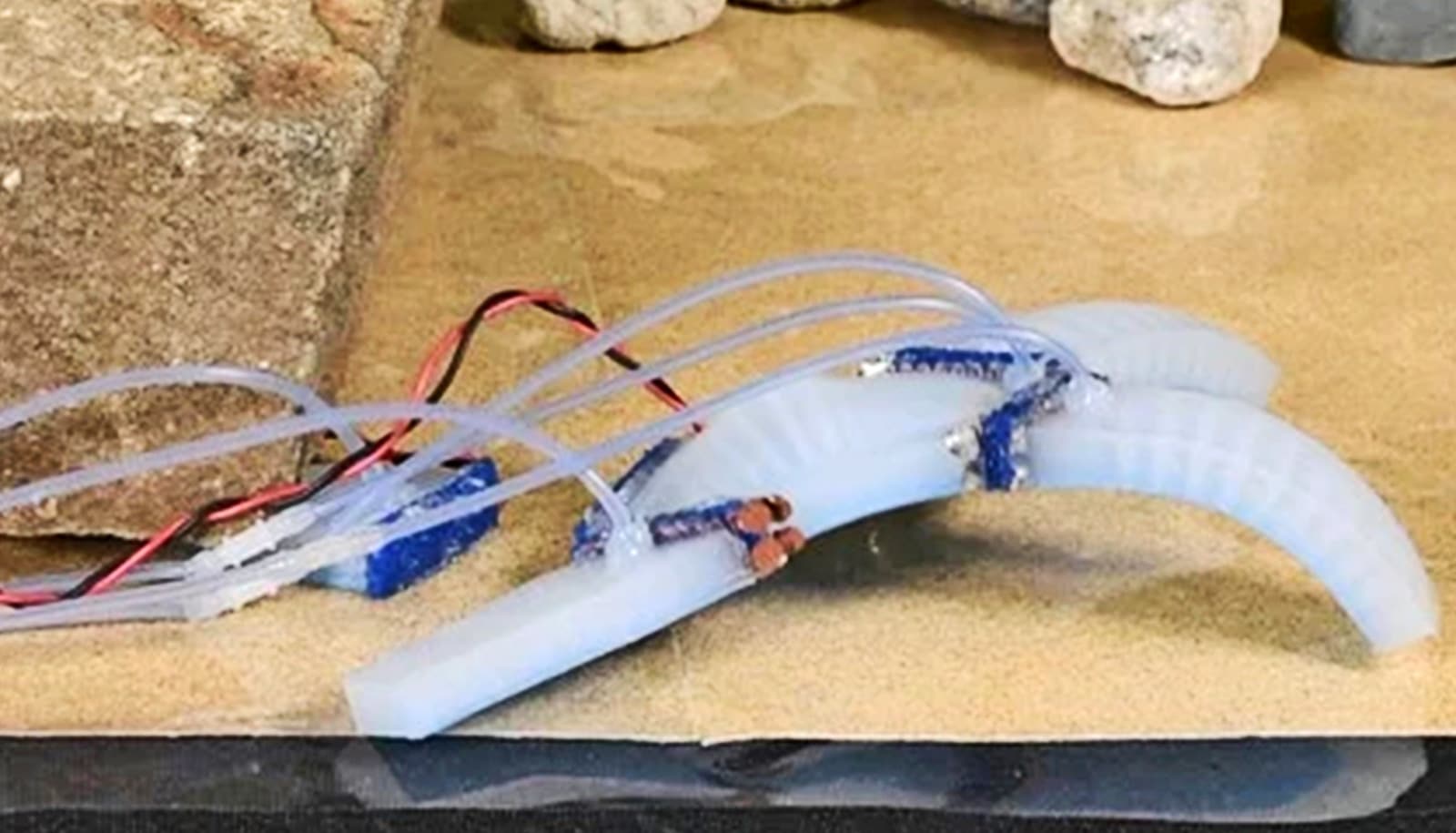

The soft robots are made of ribbon-like liquid crystal elastomers that are twisted—like a rotini noodle—and then joined together at the end to form a loop that resembles a bracelet. This “soft ring robot” is suspended on a track, which can be a thread, wire, cable, or other material. Specifically, the same ring is looped around the track two or three times, which causes the ring to hang at an angle that is parallel to the track.

When exposed to infrared light that is placed perpendicular to the track, the portion of the ribbon absorbing the most light contracts. This induces a rolling motion: the portion of the ribbon exposed to light contracts, pulling the “cooler” part of the ribbon into the light, that portion then heats up as the first section cools, causing the cycle to repeat itself over and over again. And, as the soft ring rolls, twisting on itself, it pulls itself along the track.

“As the ribbon turns, it’s like turning a screw, allowing the soft robot to move along the track—even when carrying cargo up steep angles,” Yin says.

The researchers demonstrated that the soft ring robot could navigate tracks as thin as a human hair, or as thick as a drinking straw. The soft ring robot was also able to overcome obstacles on the track, such as knots or bulges. The researchers demonstrated that the robot can also travel up or down a slope, and can carry loads more than 12 times its weight.

“We also showed that it can follow complex routes—it doesn’t have to be a straight line,” says Fangjie Qi, first author of the paper and a PhD student at NC State.

“We’ve demonstrated that it can follow curved lines, circles, three-dimensional spirals, and so on, in a controlled way. We think the adaptability of the robot when it comes to navigating complex patterns in predictable ways holds promise for its utility in practical applications.”

“We’re now thinking about specific applications for this technology, as well as adapting the soft robots to respond to inputs other than infrared light,” says Yin.

“For example, developing a soft ring robot that operates in sunlight or in response to other external energy sources.”

The paper appears in the journal Advanced Science.

Support for the work came from the National Science Foundation.

Source: North Carolina State University