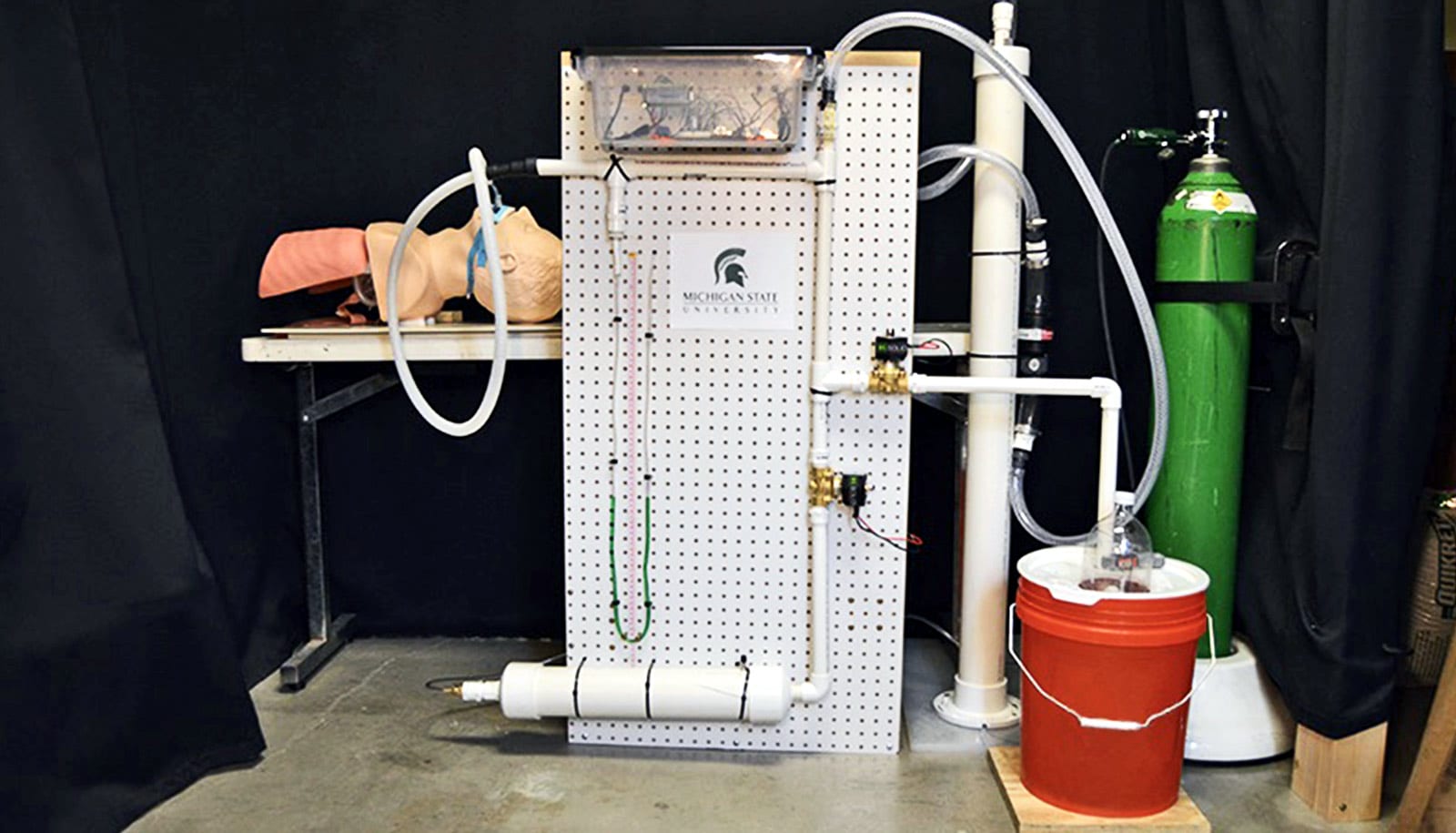

Mechanical engineers have built a ventilator prototype from commonly available parts that only cost around $200.

The project could help alleviate developing world concerns about medical equipment shortages, the researchers say.

The experimental mechanical ventilator prototype can be assembled with high volume, in-stock materials and without advanced engineering training, says Ricardo Mejia-Alvarez, assistant professor of mechanical engineering at Michigan State University.

“There is an urgent need to expand the number of patients we can ventilate mechanically,” Mejia-Alvarez says. “Given its simplicity and low cost, and if the circumstances were to require it, anybody could put together his/her own ventilator.”

The team has also developed a do-it-yourself instructional manual explaining how to assemble the prototype. Depending on the availability of supplies, it could take less than a day to assemble, Mejia-Alvarez says.

The ventilator itself is built mostly with PVC pipes and vinyl hoses, available at most hardware stores. The pressurized gas could come from any available medical grade compressed air or oxygen cylinder. The pressure control system is simple and based on an Arduino microcontroller that is cheap, reliable, and widely available in the market.

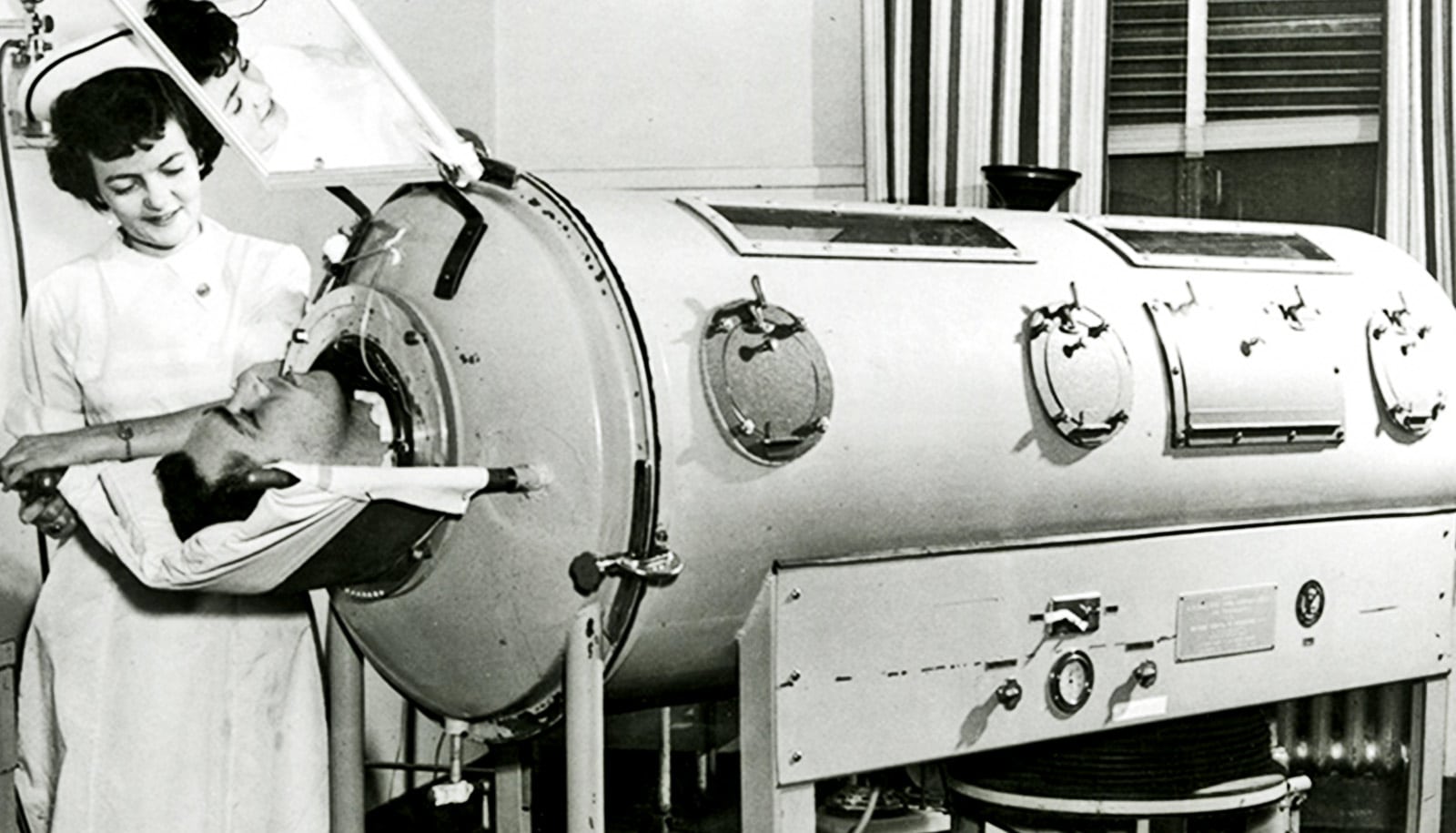

Scarcity of ventilators has forced health care providers to resort to emergency solutions, like sharing a single ventilator between two or more people. Such solutions, however, hamper the implementation of lung protective strategies, dramatically increasing the risk of ventilator-induced lung injury.

The prototype allows for precise controls when applying lung protective strategies in patients. Its low-cost, simplicity, and the wide availability of materials could allow individual hospitals to rapidly increase the number of ventilators on-site instead of sharing ventilators between several people, Mejia-Alvarez says.

“We are currently running simulation tests on artificial lungs to understand the real limits and capabilities of our ventilator and to ensure that its operation is simple,” he says

Engineers have not yet tested the ventilator prototype on human subjects, nor does it have FDA approval for use in the United States, but Mejia-Alvarez says the ventilator should be free for development and distribution in the developing world.

“It’s critical for there to be worldwide access to lifesaving equipment in the fight against COVID-19, but developing countries are extremely disadvantaged in this situation,” Mejia-Alvarez says.

The team has no plans to patent the design. US Air Force Maj. Adam Willis from the San Antonio Military Medical Center in Texas funded the work.

Source: Michigan State University