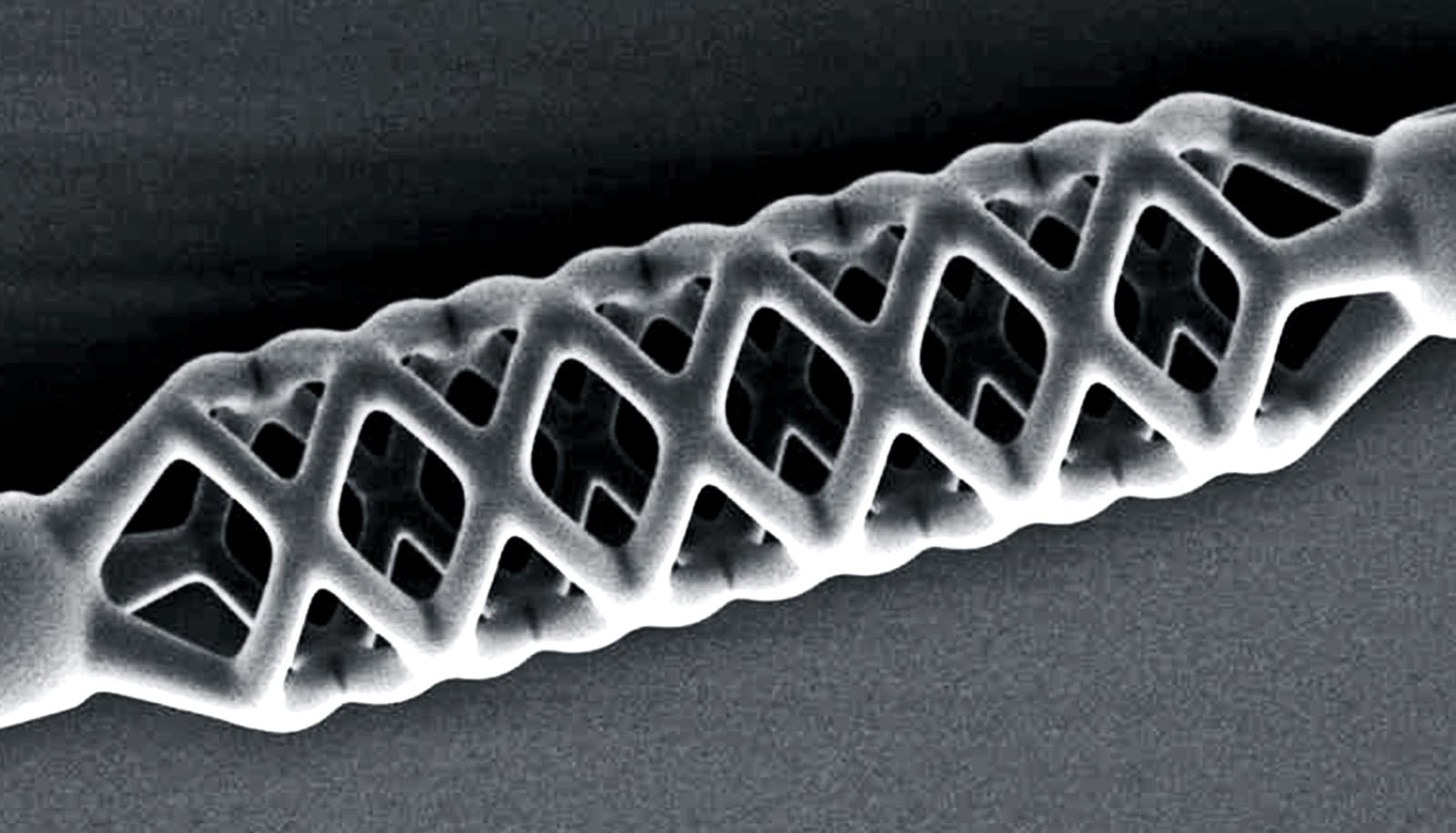

A new method for making malleable microstructures can produce vascular stents that are 40 times smaller than previously possible, researchers report.

In the future, these kinds of small stents could help to widen life-threatening constrictions of the urinary tract in fetuses in the womb.

Approximately one in every thousand children develops a urethral stricture, sometimes even when they are still a fetus in the womb.

To prevent life-threatening levels of urine from accumulating in the bladder, pediatric surgeons have to surgically remove the affected section of the urethra and sew the open ends of the tube back together again. It would be less damaging to the kidneys, however, if they could insert a stent to widen the constriction while the fetus is still in the womb.

Stents have been used to treat blocked coronary vessels for some time now, but the urinary tract in fetuses is much narrower in comparison. It’s not possible to produce stents with such small dimensions using conventional methods, which is why Gaston De Bernardis of the Kantonsspital Aarau approached researchers at the Multi-Scale Robotics Lab at ETH Zurich. The lab’s researchers have now developed a new method that allows them to produce highly detailed structures measuring less than 100 micrometers in diameter.

“We’ve printed the world’s smallest stent with features that are 40 times smaller than any produced to date,” says lead author Carmela De Marco, a fellow in Bradley Nelson’s research group at ETH.

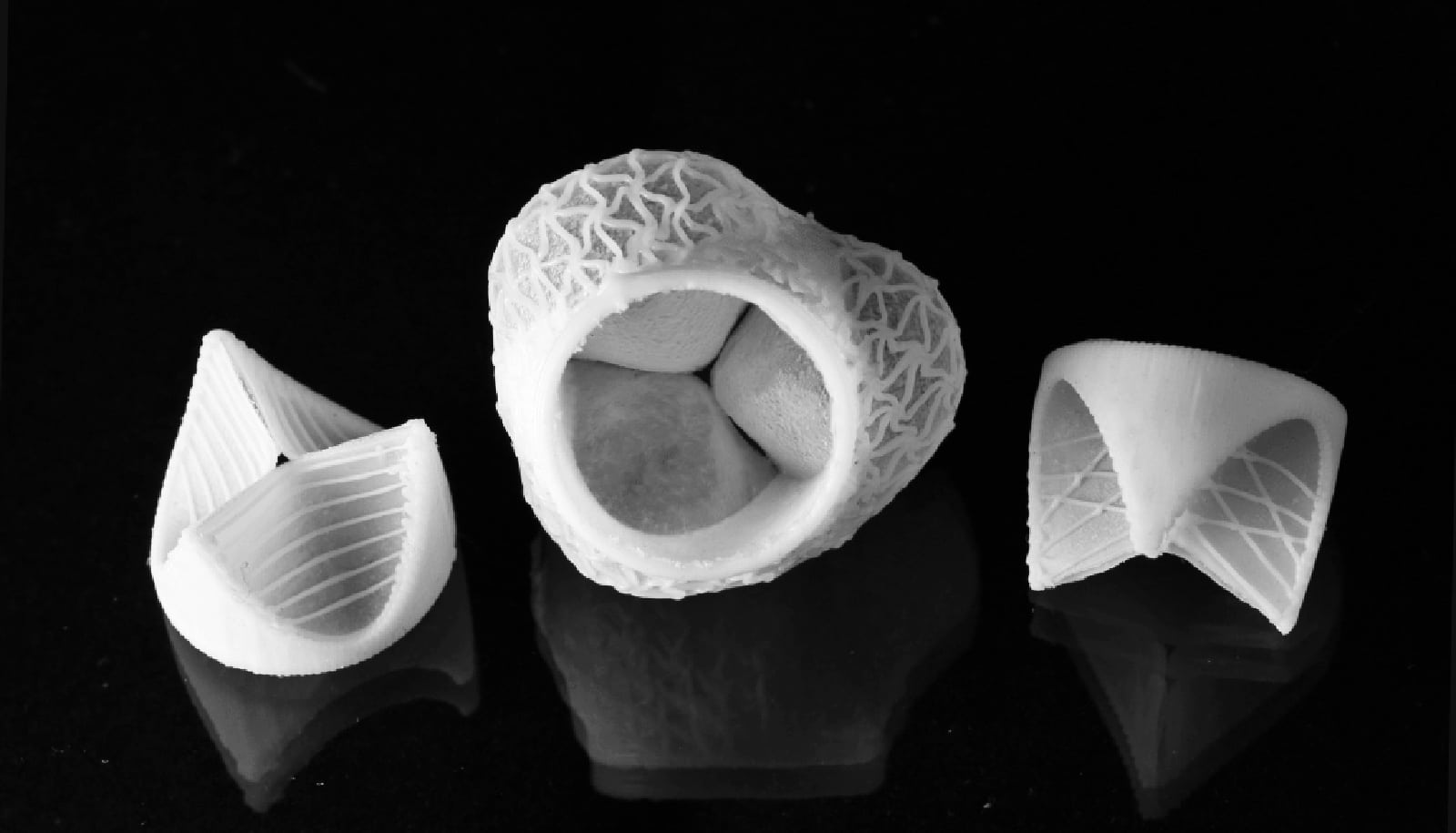

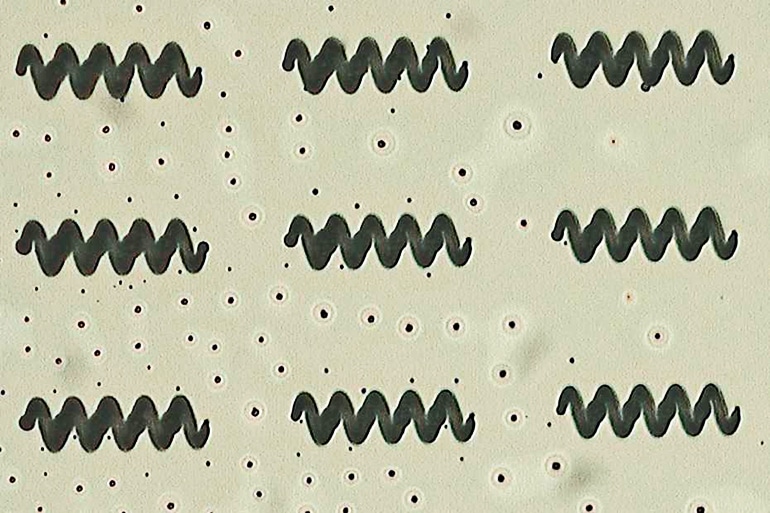

The group calls their method indirect 4D printing. They use heat from a laser beam to cut a three-dimensional template—a 3D negative—into a micromold layer that a solvent can dissolve. Next, they fill the negative with a shape-memory polymer and set the structure using UV light. In the final step, they dissolve the template in a solvent bath and the three-dimensional stent is finished.

It’s the stent’s shape-memory properties that give it its fourth dimension. Even if the material is deformed, it remembers its original shape and returns to this shape when warm.

“The shape-memory polymer is suitable for treating urethral strictures. When compressed, the stent can be pushed through the affected area. Then, once in place, it returns to its original shape and widens the constricted area of the urinary tract,” De Bernardis says.

But the stents are still a long way from finding real-world application. Before scientists can conduct human studies to show whether they are suitable for helping children with congenital urinary tract defects, they must first test the stents in animal models.

However the initial findings are promising, “We firmly believe that our results can open the door to the development of new tools for minimally invasive surgery,” De Marco says.

The research appears in Advanced Materials Technology.

Source: Ori Schipper for ETH Zurich