Chemists have developed a new method for recycling polyester.

A staggering 60 million tons of polyester are produced annually, for things like clothes, couches, and curtains. That polyester production takes a toll on the climate and environment, as only 15% of it gets recycled. The rest ends up in landfills or incinerated, which results in more carbon emissions.

“The textile industry urgently requires a better solution to handle blended fabrics like polyester/cotton. Currently, there are very few practical methods capable of recycling both cotton and plastic—it’s typically an either-or scenario,” explains postdoctoral researcher Yang Yang of the Jiwoong Lee group at the University of Copenhagen’s chemistry department.

“However, with our newly discovered technique, we can depolymerize polyester into its monomers while simultaneously recovering cotton on a scale of hundreds of grams, using an incredibly straightforward and environmentally friendly approach. This traceless catalytic methodology could be the game-changer.”

Yang is lead author of a paper on the method in the journal ACS Sustainable Chemistry & Engineering.

The new recycling method based on hartshorn salt (ammonium bicarbonate) works on PET plastic alone, as well as on PET and cotton blended materials.

“If we throw dirty plastic waste in a container, we still get good quality cotton and plastic monomer out of it. This can even be a plastic bottle with juice residue still in it. We just put it in and begin the reaction. It still works,” says Shriaya Sharma, a doctoral student of the Jiwoong Lee group and a coauthor of the study.

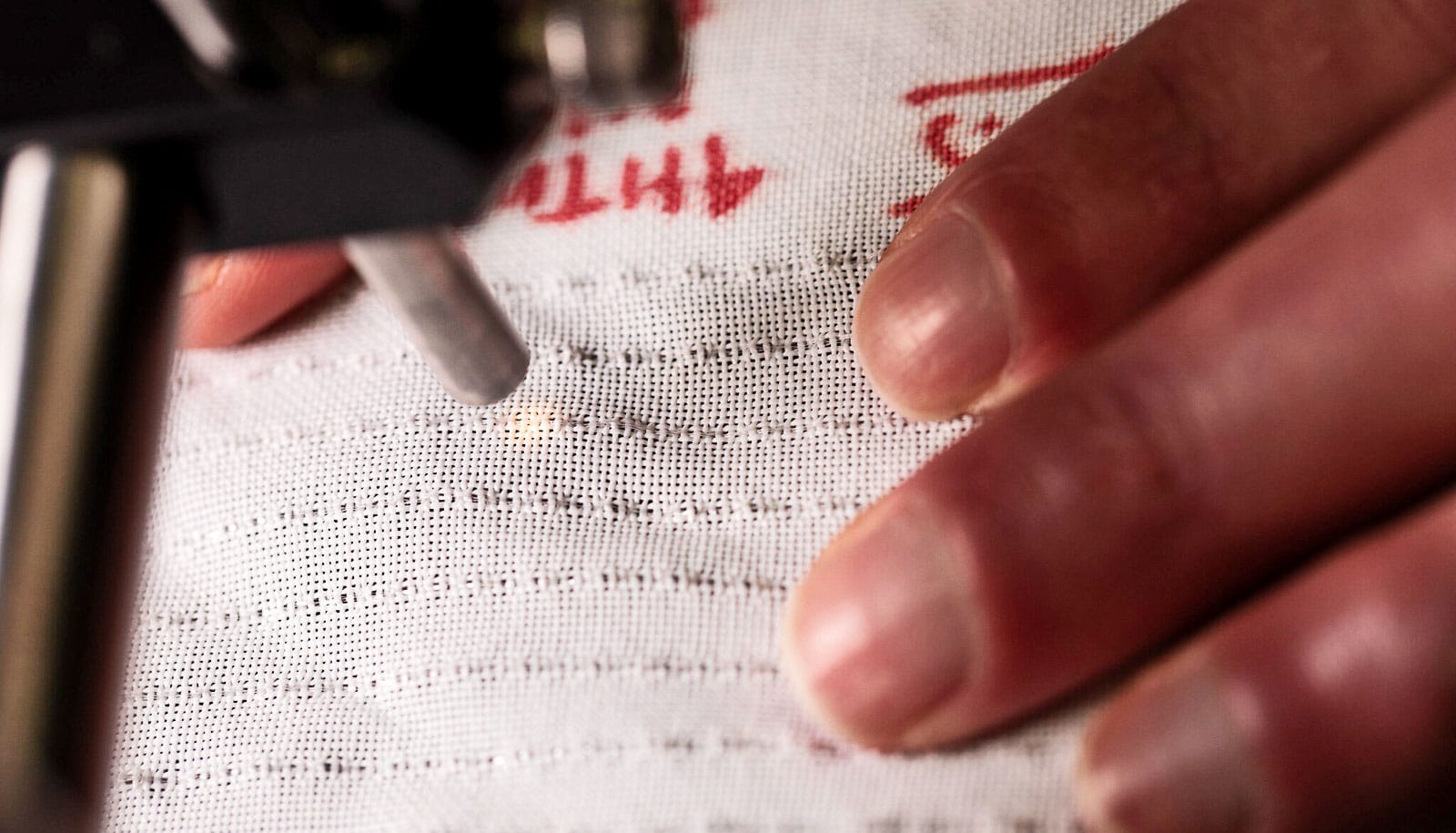

“For example, we can take a polyester dress, cut it up into small pieces and place it in a container. Then, add a bit of mild solvent, and thereafter hartshorn salt, which many people know as a leavening agent in baked goods. We then heat it all up to 160 degrees Celsius and leave it for 24 hours. The result is a liquid in which the plastic and cotton fibers settle into distinct layers. It’s a simple and cost-effective process,” says Sharma.

In the process, the hartshorn salt, also called ammonium bicarbonate, is broken down into ammonia, CO2, and water. The combination of ammonia and CO2 acts as a catalyst, triggering a selective depolymerization reaction that breaks down the polyester while preserving the cotton fibers.

Although ammonia is toxic in isolation, when combined with CO2, it becomes both environmentally friendly and safe for use. Due to the mild nature of the chemicals involved, the cotton fibers remain intact and in excellent condition.

Previously, the same research group demonstrated that CO2 could serve as a catalyst for breaking down nylon, among other things, without leaving any trace. This discovery inspired them to explore the use of hartshorn salt. Nevertheless, the researchers were pleasantly surprised when their simple recipe yielded successful results.

“At first, we were excited to see it work so well on the PET bottles alone. Then, when we discovered that it worked on polyester fabric as well, we were just ecstatic. It was indescribable. That it was so simple to perform was nearly too good to be true,” says Carlo Di Bernardo, doctoral student and study coauthor.

While the method has only been tested at the laboratory level thus far, the researchers point to its scalability and are now in contact with companies to test the method on an industrial scale.

“We’re hoping to commercialize this technology that harbors such great potential. Keeping this knowledge behind the walls of the university would be a huge waste,” says Yang.

Source: University of Copenhagen