Researchers are developing a living material that actively extracts carbon dioxide from the atmosphere.

The idea seems futuristic: Researchers are working to combine conventional materials with bacteria, algae, and fungi.

“As a building material, it could help to store CO2 directly in buildings in the future.”

The common goal: to create living materials that acquire useful properties thanks to the metabolism of microorganisms—”such as the ability to bind CO2 from the air by means of photosynthesis,” says Mark Tibbitt, professor of macromolecular engineering at ETH Zurich.

A research team led by Tibbitt has now turned this vision into reality: it has stably incorporated photosynthetic bacteria—known as cyanobacteria—into a printable gel and developed a material that is alive, grows, and actively removes carbon from the air.

The researchers recently presented their “photosynthetic living material” in a study in the journal Nature Communications.

Greener buildings

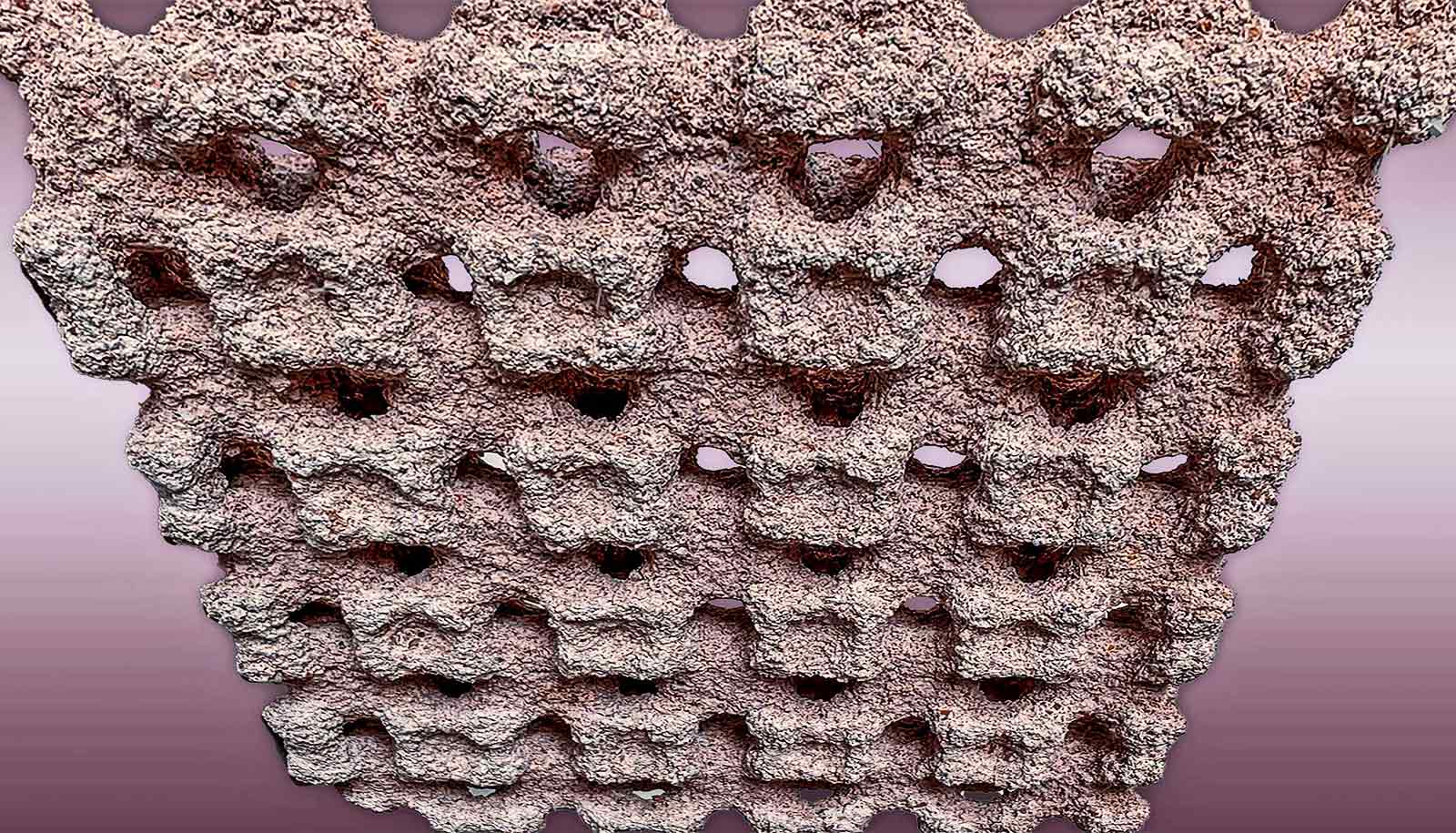

The material can be shaped using 3D printing and only requires sunlight and artificial seawater with readily available nutrients in addition to CO2 to grow.

“As a building material, it could help to store CO2 directly in buildings in the future,” says Tibbitt, who co-initiated the research into living materials at ETH Zurich.

The special thing about it? The living material absorbs much more CO2 than it binds through organic growth.

“This is because the material can store carbon not only in biomass, but also in the form of minerals—a special property of these cyanobacteria,” reveals Tibbitt.

Yifan Cui, one of the two lead authors of the study, explains: “Cyanobacteria are among the oldest life forms in the world. They are highly efficient at photosynthesis and can utilize even the weakest light to produce biomass from CO2 and water”.

At the same time, the bacteria change their chemical environment outside the cell as a result of photosynthesis, so that solid carbonates (such as lime) precipitate. These minerals represent an additional carbon sink and—in contrast to biomass—store CO2 in a more stable form.

“We utilize this ability specifically in our material,” says Cui, who is a doctoral student in Tibbitt’s research group. A practical side effect: the minerals are deposited inside the material and reinforce it mechanically. In this way, the cyanobacteria slowly harden the initially soft structures.

Laboratory tests showed that the material continuously binds CO2₂ over a period of 400 days, most of it in mineral form—around 26 milligrams of CO2 per gram of material. This is significantly more than many biological approaches and comparable to the chemical mineralization of recycled concrete (around 7 mg CO2 per gram).

The carrier material that harbors the living cells is a hydrogel—a gel made of cross-linked polymers with a high water content. Tibbitt’s team selected the polymer network so that it can transport light, CO2, water, and nutrients and allows the cells to spread evenly inside without leaving the material.

To ensure that the cyanobacteria live as long as possible and remain efficient, the researchers have also optimized the geometry of the structures using 3D printing processes to increase the surface area, increase light penetration, and promote the flow of nutrients.

“In this way, we created structures that enable light penetration and passively distribute nutrient fluid throughout the body by capillary forces,” says co-first author Dalia Dranseike.

Thanks to this design, the encapsulated cyanobacteria lived productively for more than a year, the materials researcher in Tibbitt’s team is pleased to report.

Infrastructure as a carbon sink

The researchers see their living material as a low-energy and environmentally friendly approach that can bind CO2 from the atmosphere and supplement existing chemical processes for carbon sequestration.

“In the future, we want to investigate how the material can be used as a coating for building façades to bind CO2 throughout the entire life cycle of a building,” Tibbitt says.

There is still a long way to go—but colleagues from the field of architecture have already taken up the concept and realized initial interpretations in an experimental way.

Source: ETH Zurich