Researchers are using techniques from metal additive manufacturing to embed a hidden cache of information within products to help combat counterfeit goods.

Ensuring manufactured goods and components have not been copied and replaced illegally by counterfeit goods is a high-priority concern of the manufacturing and defense industries in the United States and around the world.

A potential solution could affect areas ranging from enhancing biomedical implants to protecting national defense assets.

Researchers from Texas A&M University have developed a method of imprinting a hidden magnetic tag, encoded with authentication information, within manufactured hardware during the part fabrication process. The process holds the potential to expose counterfeit goods more easily by replacing physical tags—such as barcodes or quick response (QR) codes—with these hidden magnetic tags, which serve as permanent and unique identifiers.

The team recently published its research in the journal Additive Manufacturing.

Ensuring security and reliable authentication in manufacturing is a critical national concern, with the US investing billions of dollars in manufacturing. Without such a method readily available, it can be nearly impossible to differentiate an authentic part or component from its counterfeit copy.

“The issue is that when I come up with an idea, device, or part, it is very easy for others to copy and even fabricate it much more cheaply—though maybe at a lower quality,” says Ibrahim Karaman, professor and department head of the materials science and engineering department. “Sometimes they even put the same brand name, so how do you make sure that item isn’t yours? [The embedded magnetic tag] gives us an opportunity and a new tool to make sure that we can protect our defense and manufacturing industries.”

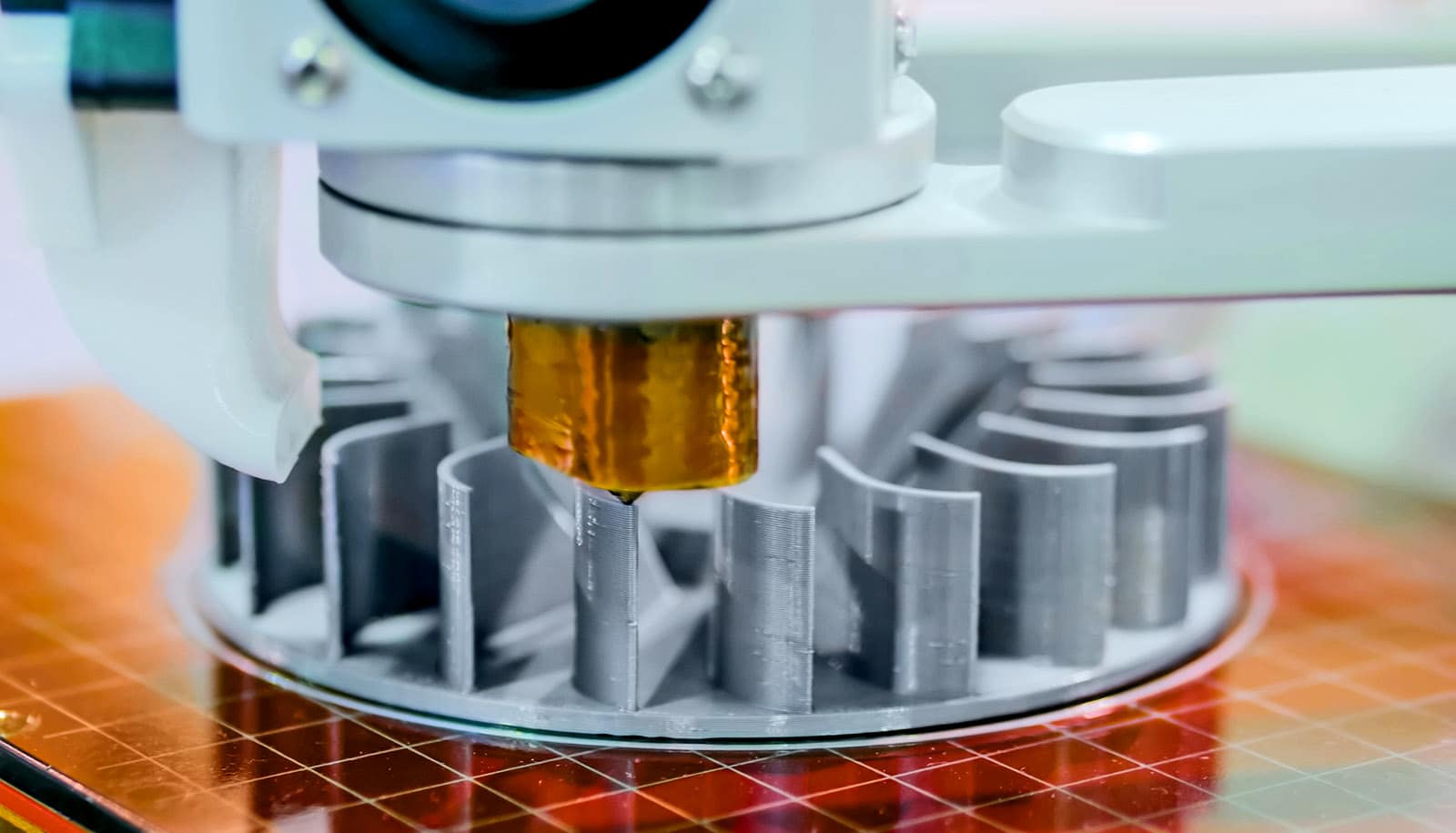

The team is implementing metal additive manufacturing techniques to accomplish its goal of successfully embedding readable magnetic tags into metal parts without compromising performance or longevity. Researchers used 3D printing to embed these magnetic tags below the surface into nonmagnetic steel hardware.

Other applications for this method include traceability, quality control, and more, largely depending on the industry that uses it.

Once embedded into a nonmagnetic item, the magnetic tag is readable using a magnetic sensor device—such as a smartphone—by scanning near the correct location on the product.

While other methods exist for imprinting information, they primarily require sophisticated and costly equipment.

“Different approaches have been used to try to locally change the properties of the metals during the manufacturing process to be able to codify information within the part,” says Daniel Salas Mula, a researcher with the Texas A&M Engineering Experiment Station.

“This is the first time that magnetic properties of the material are being used in this way to introduce information within a nonmagnetic part, specifically for the 3D printing of metals.”

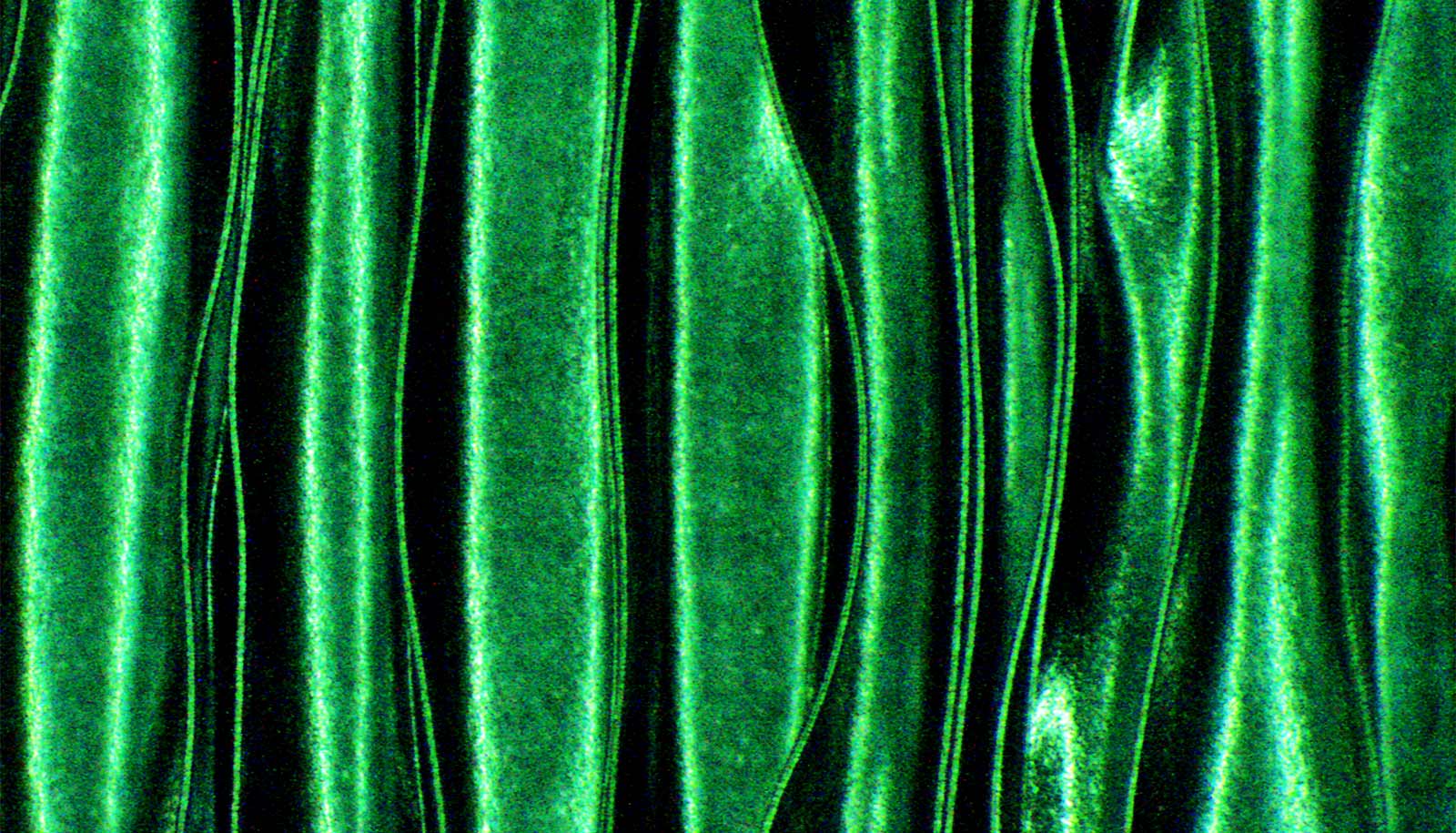

Doctoral student Deniz Ebeperi says that to map the magnetic reading of the part, the team created a custom three-axis magnetic sensor capable of mapping the surface and revealing the regions where the embedded magnetic tag was accessible.

While the system is more secure than a physical tag or code located on the exterior of an item, the team is still working to improve the complexity of the method’s security.

As the project continues, Karaman says the next steps include developing a more secure method of reading the information, possibly through the implementation of a physical “dual-authentication” requiring the user to apply a specific treatment or stimulus to unlock access to the magnetic tag.

Additional collaborators are from Texas A&M University and Purdue University. The project had support from the SecureAmerica Institute.

Source: Texas A&M University