Researchers have developed a method that uses 3D printing to create products containing magnets.

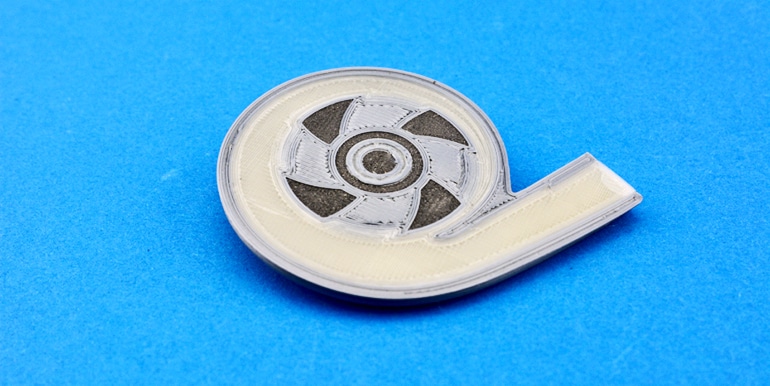

When Kai von Petersdorff-Campen decided to make an artificial heart pump using 3D printing, he didn’t expect that his project would attract so much attention. The piece of plastic that he took from the printer after 15 hours was of very low quality. But as the ensuing test showed, it worked—and that was the key point.

“My goal was not to make a good heart pump, but to demonstrate the principle of how it can be produced in a single step,” says Petersdorff-Campen.

Petersdorff-Campen, a doctoral student in the mechanical and process engineering department at ETH Zurich, developed the prototypes this spring within just a few months.

The significant part of Petersdorff-Campen’s project is not the heart pump itself; this is simply an example application of the 3D printing method he developed.

Artificial heart pumps are not only geometrically complex products, but, more importantly, they contain magnets—and research on 3D printing with magnets is still in its infancy. Petersdorff-Campen’s heart pump is one of the first prototypes with magnetic components manufactured using 3D printing.

Petersdorff-Campen calls his newly developed method “embedded magnet printing.” The key is to ensure that the magnets are printed directly in the plastic. Magnetic powder and plastic are mixed before printing and processed into strands known as filaments. These then go through the 3D printer, which processes them in a similar way to conventional 3D printing—Petersdorff-Campen chose the FDM method. A nozzle automatically outputs the computer-generated form, with its various components. Finally, the printed piece is magnetized in an external field.

One of the biggest difficulties was developing the filaments: the more magnetic powder in the granulate mix, the stronger the magnet, but the more brittle the end product. However, in order for the filaments to be pressed through the 3D printer, they must be reasonably flexible. Petersdorff-Campen has now succeeded in finding a happy medium.

“We tested various plastics and mixes, until the filaments were flexible enough for printing but still had enough magnetic force,” he says.

The method is reported in Applied Sciences. The reactions varied, he explains: “Some people are already asking where they can order the material.”

Others criticized that the 3D printing is not suitable for the production of medical devices, due to the various approval processes. “That was not my focus, however,” Petersdorff-Campen says. “I simply wanted to show the principle.” He’s sure that it’s worth it for scientists and developers to develop the idea further.

Even though the method may not be suitable for heart pumps, the potential of 3D printing of magnets is huge: they are a key component in much more than just medical devices. They’re used in electric motors, such as those in numerous technical household devices, including a computer’s hard drive, loudspeakers, and microwaves.

Today, complex injection molding produces geometrically complex components with magnets, but 3D printing could make this process significantly quicker and therefore cheaper.

However, that’s still a long way off, Petersdorff-Campen says. “There is still a lot to improve in terms of material and processing.” For example, his heart pump may have passed the initial tests and pumped 2.5 liters per minute with 1,000 rotations, but this does not yet meet the standards required in practice. “I wouldn’t want to have such a device implanted.”

The project is part of Zurich Heart under the umbrella of University Medicine Zurich.

Source: Andreas Eberhard for ETH Zurich