Researchers have taken a step forward in developing a new armband that can track the heart’s electrical activity without requiring bulky wiring or sticky gel on the skin.

Specifically, they determined the ideal placement for three electrodes in the band design, and how tightly the band needs to be to best detect electrical signals from the heart.

The findings are the latest advance in a multi-institutional effort to develop an armband that takes electrocardiogram, or ECG, measurements in order to track heart rate. Researchers ultimately envision a device that could be worn as an arm sleeve throughout the day. Energy from body heat or movement would supply the power.

“This study is the first step in identifying all of the components to make the armband a reality,” says first author Braden M. Li, a PhD candidate in the Wilson College of Textiles at North Carolina State University.

“We identified the ideal electrode location to gather heart signals and figured out how the armband pressure affects the electrocardiogram quality.”

Researchers studied the placement of electrodes in various locations on a volunteer’s upper left arm in order to identify the best placement of three electrodes for tracking the heart’s electrical activity. They identified the best placement from among 50 different combinations.

While electrodes are conventionally used “wet,” or along with a gel substance in ECG devices, researchers are working on a design that would use dry electrodes since they have the potential to be used over a longer period of time as part of a wearable device.

They also measured the pressure and heart signal of three different sizes of the band in order to understand how tightly it needs to be worn.

“If we don’t have enough compression, then we don’t get the same quality of data that we need,” says senior author Jesse S. Jur, professor of textile engineering, chemistry, and science.

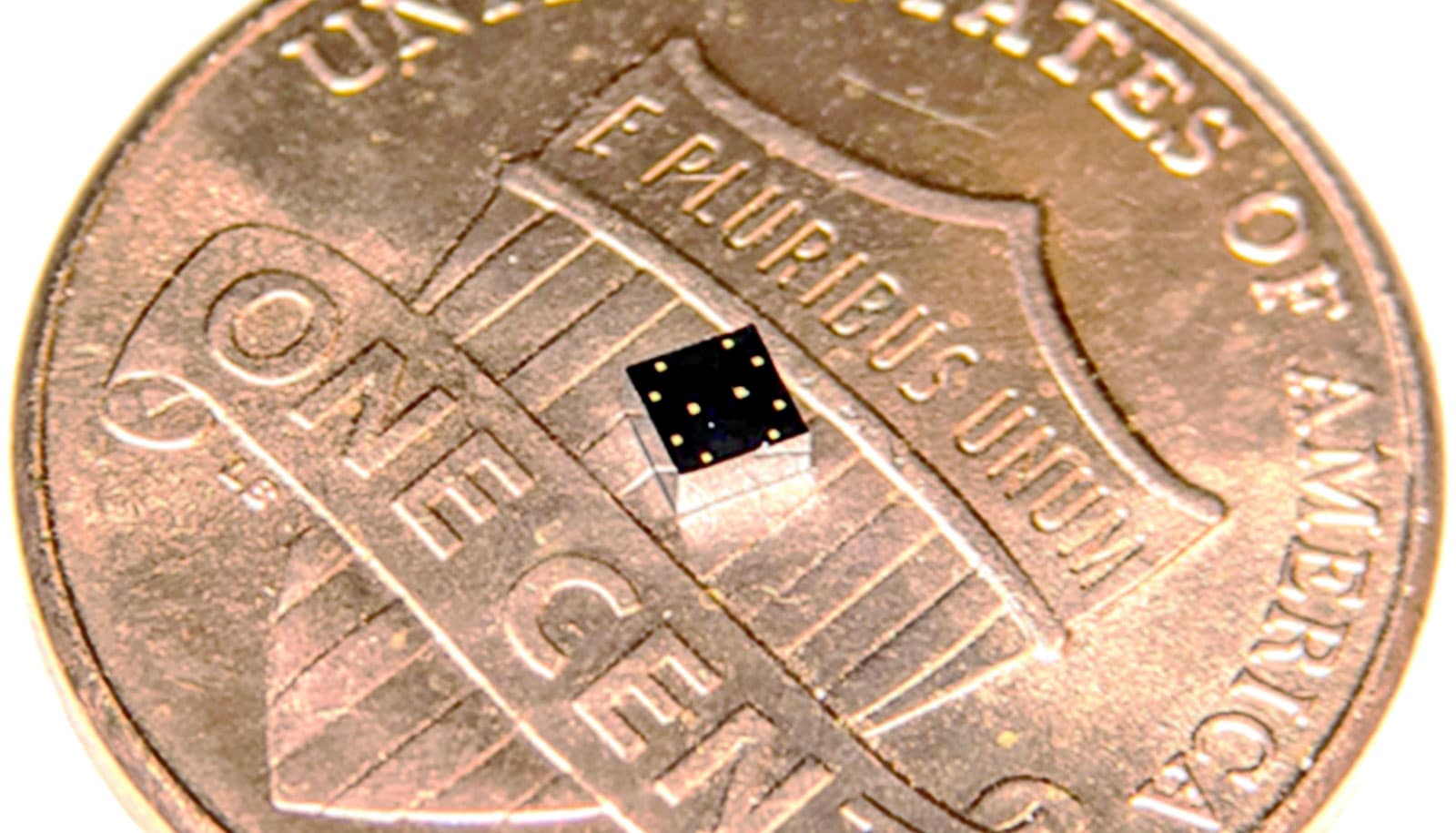

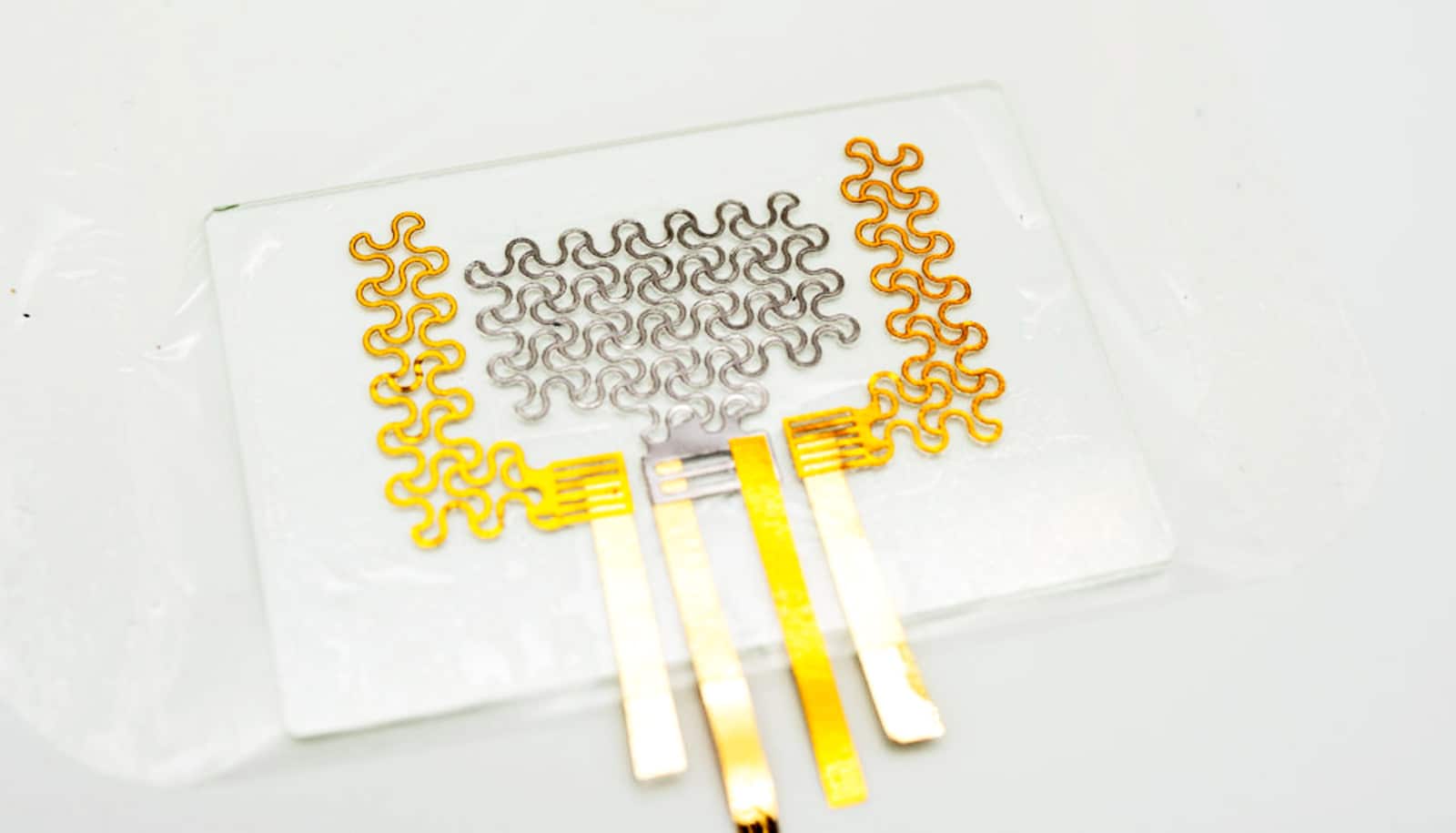

To make the band prototype, the researchers screen printed the electrodes into a plastic film through a method uncovered in a previous study in Jur’s lab. Then, they heat pressed the electrodes on to a polyester and spandex fabric.

“Screen printing is a very traditional process in textile manufacturing,” Li says. “We wanted to choose a manufacturing process that could be easily translated into the textile process.”

The work is part of a multi-institution research effort conducted through the National Science Foundation-funded, engineering research-based Center for Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST). The researchers in the center are working to develop wearable devices that the body’s own thermal or mechanical energy can power. For the armband, they are working on the design to get the best heart signal while using the least amount of energy.

They are designing the armband with three electrodes, rather than with 12, so that the wearer could potentially power it. While increasing the number of leads could capture the heart’s electrical signal with greater accuracy, they are working on a design that a person of any body type could easily wear.

“Part of the goal for the ASSIST center is to design self-powered, wearable electronics,” Jur says. “We’re always balancing how much power would be required for the sensors system, data processing, and communication in order to match that for the power you might be able to harvest from the body.”

The study appears in IEEE Sensors Journal. The US National Science Foundation funded the work.

Source: NC State