Researchers have created the world’s smallest fully programmable, autonomous robots.

These microscopic swimming machines can independently sense and respond to their surroundings, operate for months, and cost just a penny each.

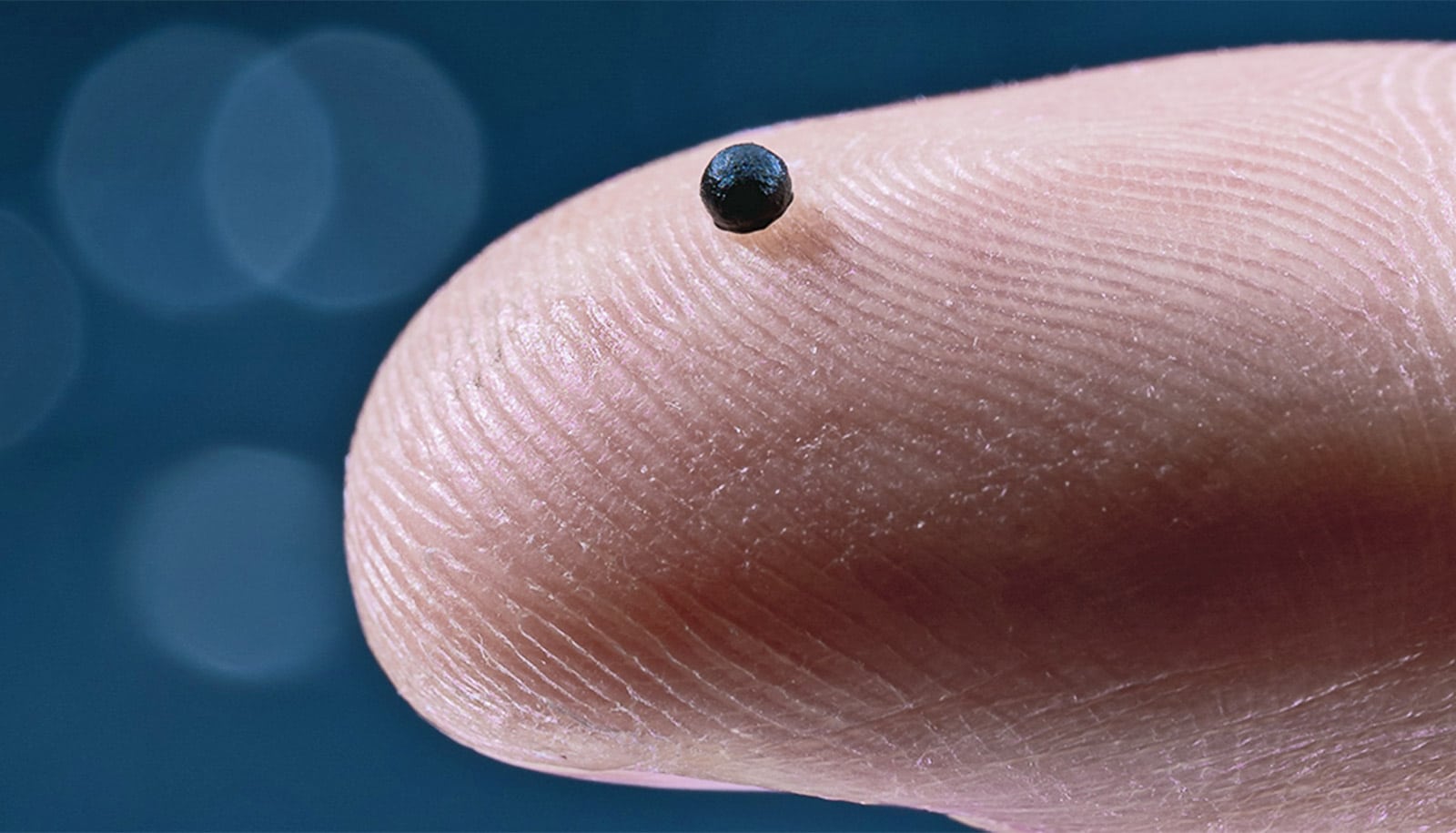

Barely visible to the naked eye, each robot measures about 0.2 by 0.3 by 0.05 millimeters, operating at the scale of many microorganisms. They can be programmed to move in complex patterns, sense local temperatures and adjust their paths in response.

These light-powered robots, developed with primary support from the National Science Foundation, could advance medicine by monitoring the health of individual cells and aid manufacturing by helping construct microscale devices, the researchers say.

“We’ve made autonomous robots 10,000 times smaller,” says Marc Miskin, assistant professor in electrical and systems engineering at the University of Pennsyvlania and senior author of a pair of studies in Science Robotics and the Proceedings of the National Academy of Sciences. “That opens up an entirely new scale for programmable robots.”

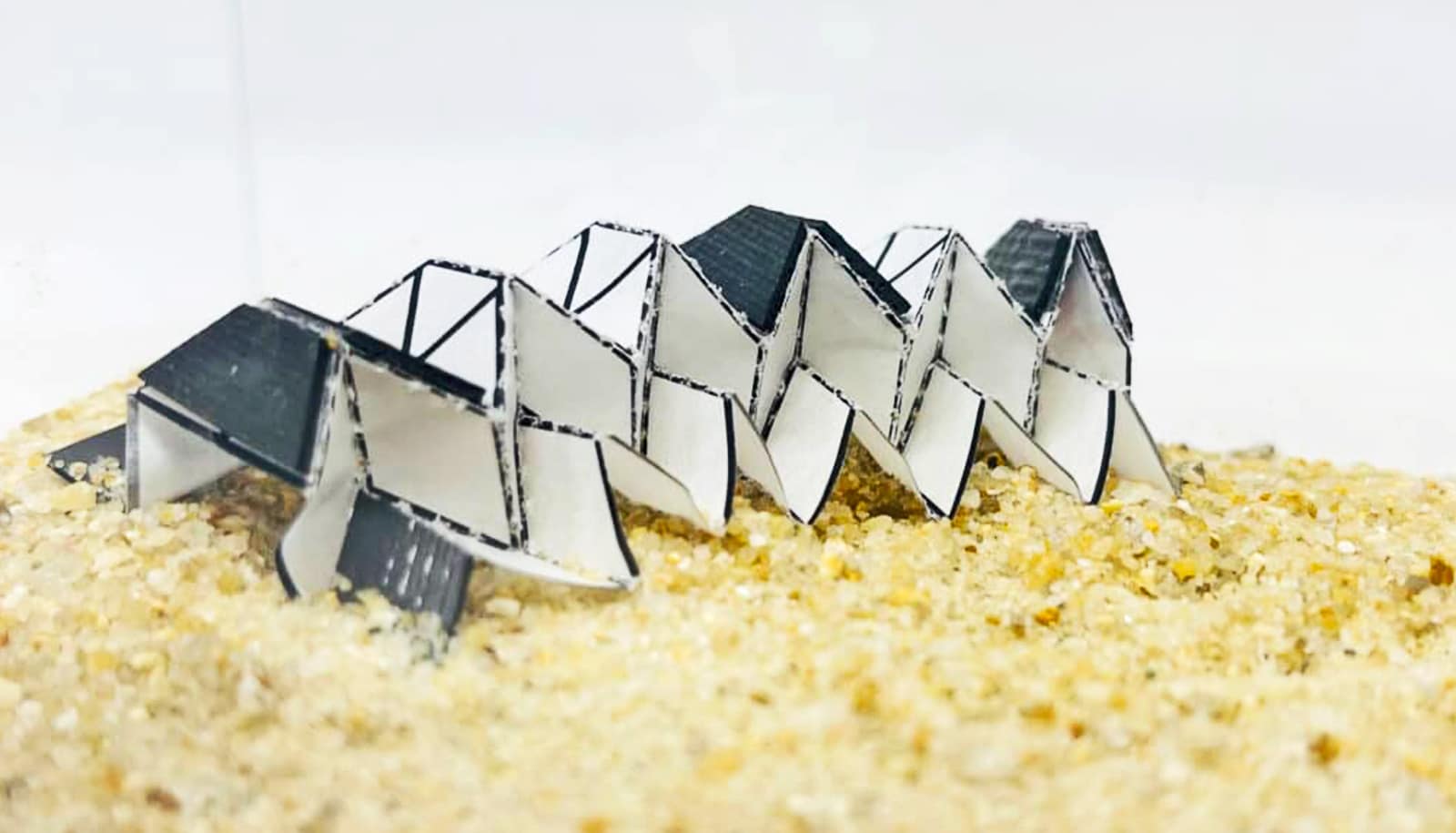

The robots can move in complex patterns and even travel in coordinated groups, much like a school of fish. And because their propulsion system has no moving parts, the robots are extremely durable—easy to transfer with a micropipette and capable of swimming for months.

For decades, electronics have gotten smaller and smaller, epitomized by the record-setting sub-millimeter computers developed in the lab of David Blaauw and Dennis Sylvester, professors of electrical and computer engineering at UM. Yet robots have struggled to keep pace, in part because independent motion is exceptionally difficult for microscale devices—a problem Miskin says has stalled the field for 40 years, until now.

“We saw that Penn Engineering’s propulsion system and our tiny computers were just made for each other,” says Blaauw, a senior author of the Science Robotics study.

Operating at the microscale in water, drag and viscosity are so large that Miskin says it’s like moving the robot through tar. His team’s propulsion design gets around this by turning the problem around. Instead of trying to move themselves, these robots move the water. They generate an electrical field that nudges ions in the surrounding liquid. Those ions, in turn, push on nearby water molecules, generating force to move the robot. This mechanism is described in PNAS.

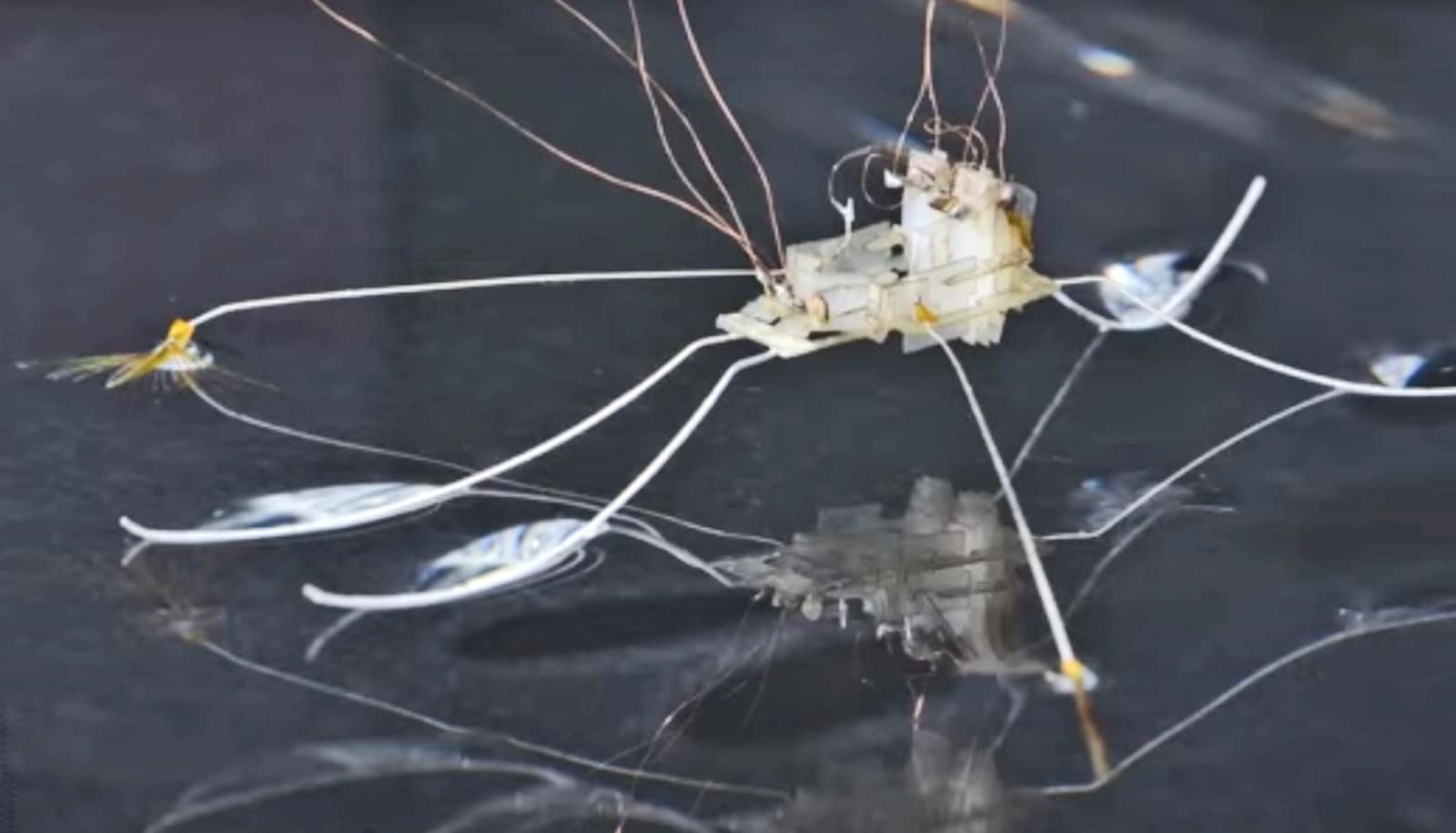

On the computing side, Blaauw’s team needed to run the robot’s program on 75 nanowatts of power, which he says is 100,000 times less than a smart watch requires. To get even that tiny amount of power, the solar panels take up most of the robot.

“We had to totally rethink the computer program instructions, condensing what conventionally would require many instructions for propulsion control into a single, special instruction to help us shrink the program’s length to fit in the robot’s tiny memory,” Blaauw says.

The robots are both powered and programmed by light pulses, and each has their own unique identifier for individualized programming. This capability could enable a team of robots to each take a different part of a group task.

The batch of robots described in Science Robotics is equipped with sensors that detect temperature to within a third of a degree Celsius. They could move toward areas of increasing temperature or report temperature as a proxy for cellular activity—allowing them to monitor the health of individual cells. They reported these temperatures by wiggling, much like the “waggle dance” honeybees use to communicate, Blaauw notes. Future versions of the robots could store more complex programs, move faster, integrate new sensors, or operate in more challenging environments.

“This is really just the first chapter,” Miskin says. “We’ve shown that you can put a brain, a sensor, and a motor into something almost too small to see, and have it survive and work for months. Once you have that foundation, you can layer on all kinds of intelligence and functionality. It opens the door to a whole new future for robotics at the microscale.”

Additional support for this project came from the University of Pennsylvania Office of the President, Air Force Office of Scientific Research, Army Research Office, Packard Foundation, Sloan Foundation, and Fujitsu Semiconductors.

Source: University of Michigan