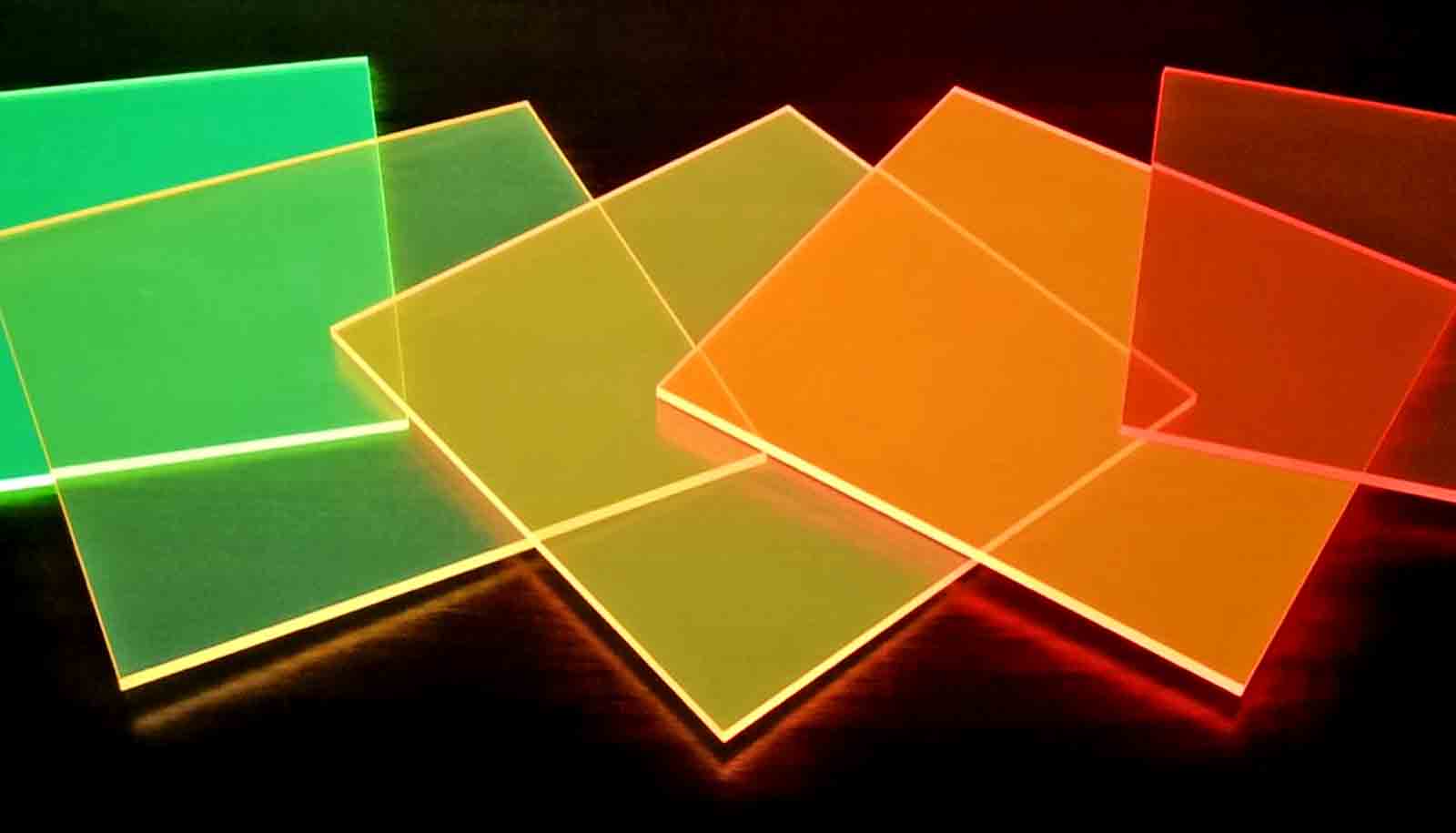

It’s easy to tune the color of new fluorescent polymers, report researchers.

Potential uses include biomedicine, security printing, and solar energy.

Around the world, a huge amount of research and development work is underway on carbon-containing, or organic, molecules that emit colored light after appropriate excitation. The display industry and the development of biomedical imaging techniques drives this work.

While precise color tuning in organic fluorescent dyes has typically involved mixing different molecules, ETH Zurich researchers have now developed an approach that can generate a broad palette of colors with chemical adjustments within the molecules themselves.

Yinyin Bao, a group leader in the group of professor Jean-Christophe Leroux, and his team of scientists turned to fluorescent organic polymers. You can think of these polymers as moving chains of varying lengths.

“The chains have a symmetrical structure, and two components within them contribute to the fluorescence,” Bao explains. “One component, called the fluorophore, sits in the middle of the chain, while the other component occurs once at each of the chain’s two ends.”

Joining the fluorophore in the middle of the chain with each end of the chain are links whose number and structure scientists can adjust. If the polymer chain is bent so that one of its ends comes to lie near the fluorophore and the chain is simultaneously irradiated with UV light, it fluoresces.

The scientists have now been able to show that the fluorescence color depends not only on the structure of the chain links and ends, but also on the number of chain links. “It’s the interaction of the chain end and the fluorophore that’s responsible for the fluorescence of these polymers,” Bao says: “The distance between the two components affects how they interact and thus the color that’s emitted.”

Using a method called living polymerization, the researchers can regulate the number of chain links. First, they gradually grow the chain by a slow process of attaching building blocks to the fluorophore. Once the desired length is reached, the scientists can terminate the process and simultaneously generate the chain end molecule. This is how the researchers produced polymers with different colors: with fewer than 18 building blocks, the molecules fluoresce yellow; with 25 chain links, green; and with 44 or more links, blue.

“What’s special about this is that these differently luminescent polymers are all composed of the exact same components. The only difference is the chain length,” Bao says.

The research team reports the work in the journal Science Advances. Currently, the researchers can produce fluorescent polymers in yellow, green, and blue, but they are working on extending the principle to include other colors, including red.

These new fluorescent polymers can’t be used directly as OLEDs (organic LEDs) in displays because their electrical conductivity is not sufficiently high, Bao explains. However, it ought to be possible to combine the polymers with semiconducting molecules in order to produce wide color range OLEDs in a simple way.

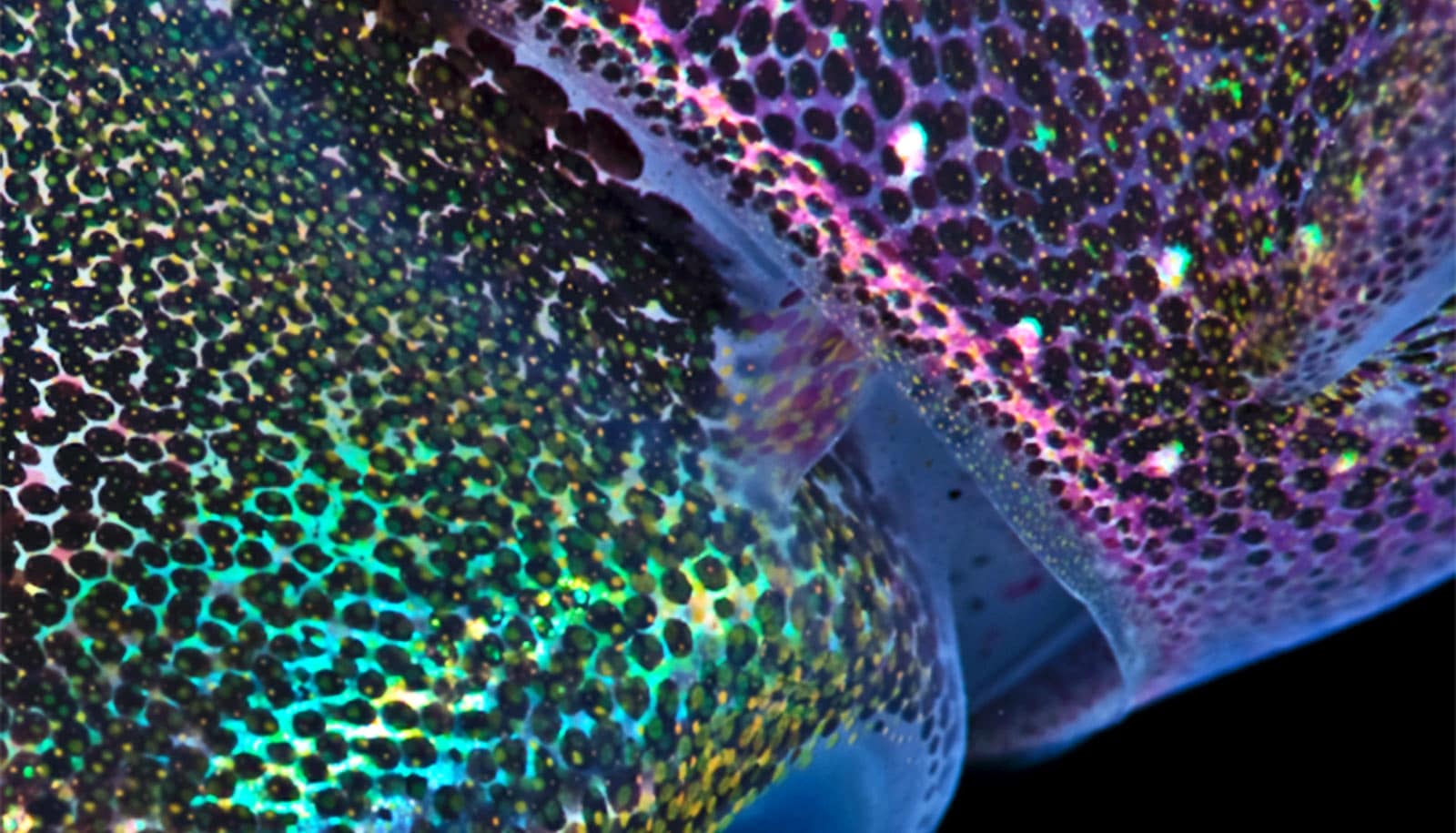

Used in concentrated solar power plants, they could also collect sunlight more efficiently and thus increase the plants’ efficiency. Bao sees their main areas of application in laboratory diagnostic procedures that use fluorescence, for example in PCR, as well as in microscopy and imaging procedures in cell biology and medicine. Other potential uses would be as security features on banknotes and certificates or in passports.

Source: ETH Zurich