A thin shell of soft polymer can help keep knotty ceramic structures from shattering, researchers report.

Ceramics made with 3D printers crack under stress like any plate or bowl. But covered in a soft polymer cured under ultraviolet light, the same materials stand a far better chance of keeping their structural integrity, much like a car windshield’s treated glass is less likely to shatter.

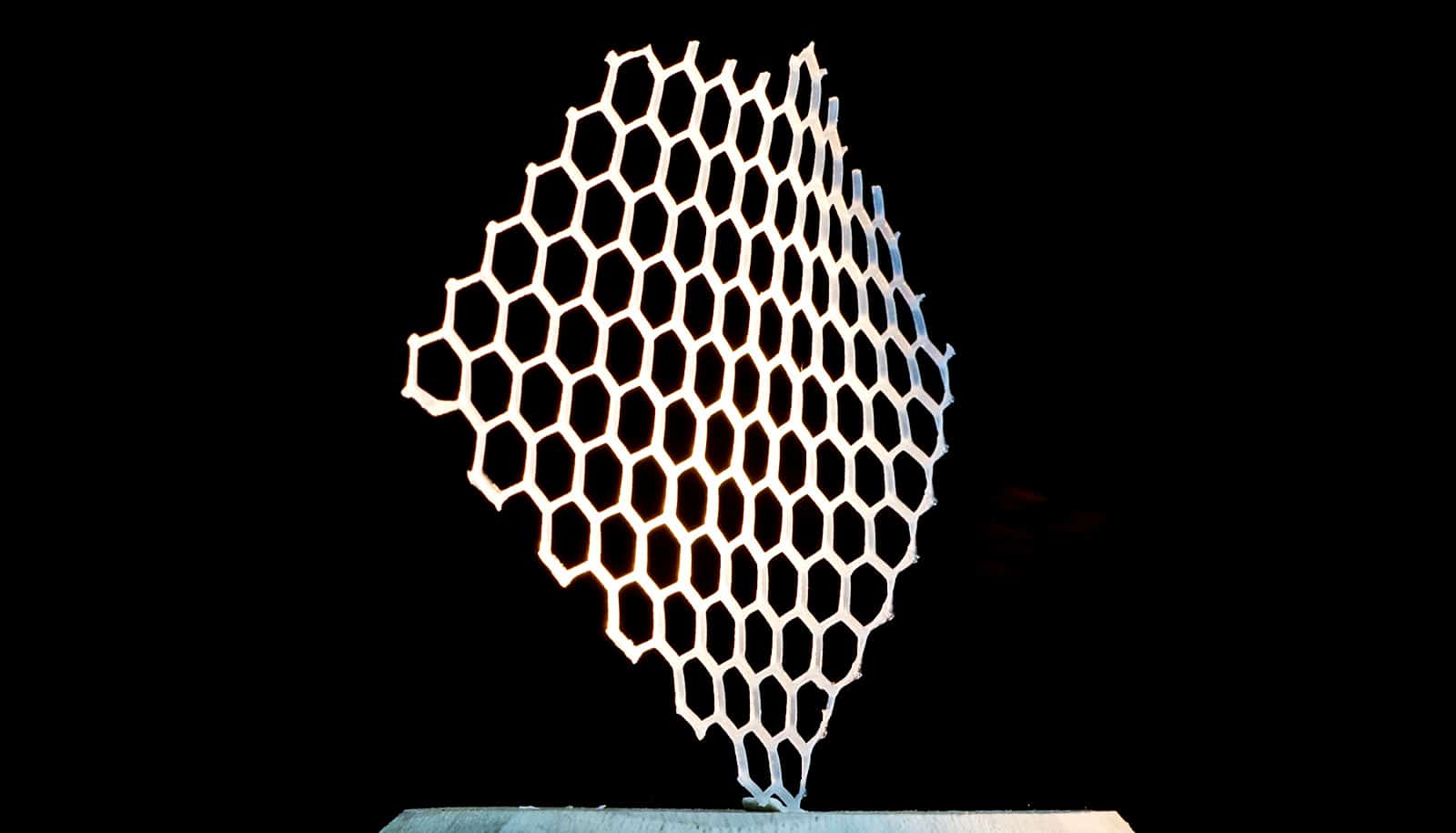

The research demonstrates the concept on schwarzites, complex lattices that for decades existed only as theory but can now be made with 3D printers. With added polymers, they come to resemble structures found in nature like seashells and bones that consist of hardened platelets in a biopolymer matrix.

Schwarzites, named for German scientist Hermann Schwarz, who hypothesized in the 1880s the “negatively curved” structures could be used wherever very strong but lightweight materials are needed, such as batteries, bones, and buildings.

The researchers proved through experiments and simulations that a coating of polymer no more than 100 microns thick will make fragile schwarzites up to 4.5 times more resistant to catastrophic fractures. The structures may still crack under pressure, but they won’t fall apart.

“We’ve clearly seen that the uncoated structures are very brittle,” says Muhammad Rahman, a materials scientist and research scientist at Rice University. “But when we put the coated structures under compression, they will take the load until they completely break. And interestingly, even then they don’t completely break into pieces. They remain enclosed like laminated glass.”

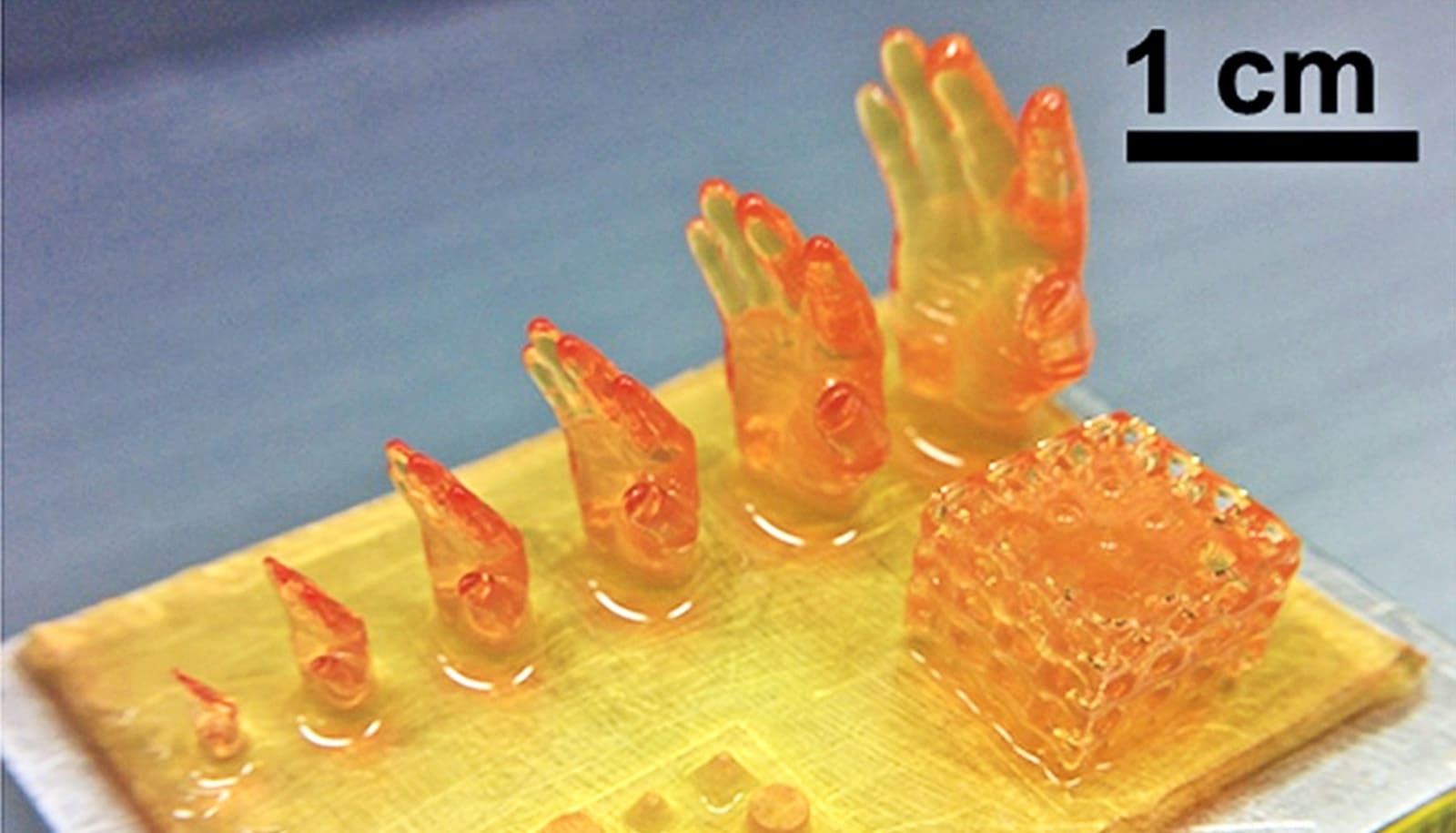

The team, with members in Hungary, Canada, and India, created computer models of the structures and printed them with a polymer-infused ceramic “ink.” The ceramic was cured on the fly by ultraviolet lights in the printer, and then dipped in polymer and cured again.

Along with uncoated control units, the intricate blocks were then subjected to high pressure. The control schwarzites shattered as expected, but the polymer coating prevented cracks from propagating in the others, allowing the structures to keep their form.

The researchers also compared the schwarzites to coated solid ceramics and found the porous structures were inherently tougher.

“The architecture definitely has a role,” says graduate student Seyed Mohammad Sajadi, lead author of the paper, published in Science Advances. “We saw that if we coat a solid structure, the effect of the polymer was not as effective as with the schwarzite.”

The coatings acted a bit like the natural materials they mimic, as the polymer infuses defects in the ceramics and enhances their resistance, says Pulickel Ajayan, chair of the materials science and nanoengineering department and professor in engineering and a professor of chemistry.

Several structural applications could benefit from polymer-enhanced ceramics. Their biocompatibility could also eventually make them suitable for prosthetics, Rahman says.

“I’m pretty sure that if we can optimize these structures topologically, they also show good promise for use as bioscaffolds.”

Additional coauthors are from the University of Szeged, Hungary; ANSYS Inc.; the University of Houston; the University of Toronto; Aramco Americas; the University of Maryland; the Indian Institute of Technology Kharagpur, India; and Rice.

The Hungarian Research Development and Innovation Office, the Ministry for Innovation and Technology in Hungary, and supercomputing resources at the University of Maryland and the Maryland Advanced Research Computing Center supported the work.

Source: Rice University