Researchers have developed a material called a “pluripotent plastic” that has the ability to take on many forms.

Drifting at sea, isolated on a space station, or stuck in a war zone, engineers trying to build new things or patch together a repair are often constrained by the materials they have at hand.

“We want to reframe the way we think about designing materials.”

But what if they had one single polymer that they could coax into anything from a rubber band-like material or a ball of silly putty to a flexible sheet of plastic or a stiff, molded device?

Like pluripotent stem cells which can give rise to any type of adult cell in the human body, the new kind of plastic, described in the journal Science, can take on many forms.

“We believe, this is the first example of a synthetic material that exhibits pluripotent behavior,” says Stuart Rowan, a professor at the University of Chicago’s Pritzker School of Molecular Engineering and senior author of the new work. “We believe that it paves the way toward a different way of thinking material design.”

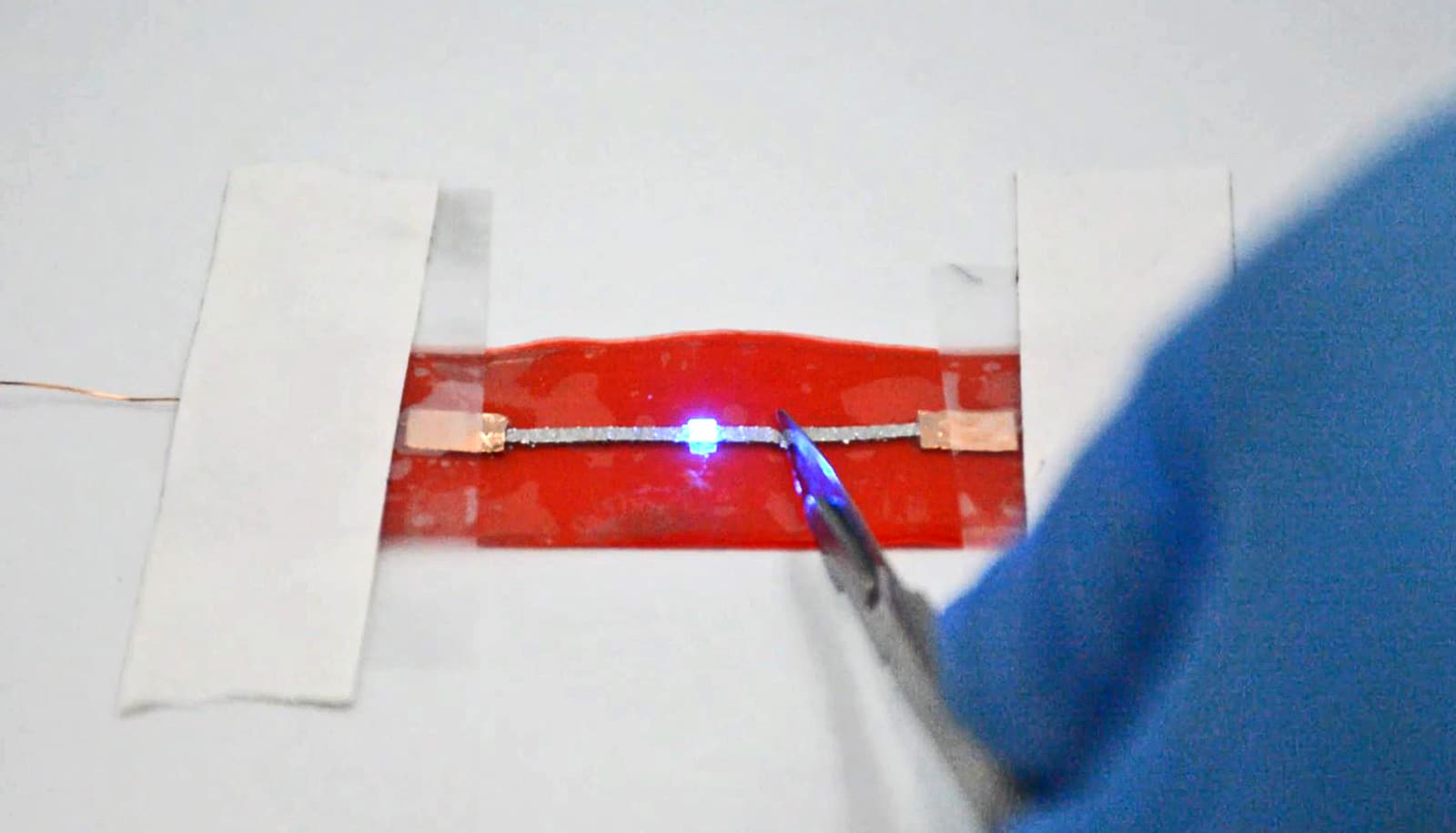

The pluripotent material is made up of polymers containing “dynamic covalent bonds,” which can break and reform reversibly. Heating the material only to low temperatures (around 140° Fahrenheit, or 60 °C) allows the formation of more bonds, resulting in stiff, high-strength materials at room temperature. These could be used to make plastic utensils, among other things.

However, heating to higher temperatures (around 230°F/110 °C) results in fewer bonds being formed and, in turn, a more soft, extensible material that can be used for instance, as a pressure-sensitive adhesive.

“We were surprised by how many different mechanical properties we could get,” says Boynton. “From this single feedstock material, we can turn it into something that behaves like a hard, high-strength material or something that’s quite flexible, like a rubber band.”

By adjusting the temperature between the two extremes, the researchers showed that they could fine-tune the properties of the materials, giving them a variety of properties and functions.

Moreover, the resulting material—although stable at room temperature—could be tempered again at a different temperature to access a new and different state.

“If you’re going to live on the moon or Mars, you can’t take a bunch of materials with you, and you don’t have Amazon Prime shipping, so it’d be great if you have this one material that you can turn into a bunch of different stuff,” says Boynton.

In addition to being employed as on-demand reuse materials in resource-scare environments, such as on the moon or Mars, this work also opens the door to different approaches to plastic recycling (where there is no need to separate out the different plastics we use today).

The team is now investigating how to improve the range of mechanical properties that can be imbued in their pluripotent materials with the goal of creating materials to replace current plastics as well as materials with new functional properties.

“We want to reframe the way we think about designing materials,” says Rowan. “Instead of designing one material for one application, let’s flip that on its head and see if we can make one material that can be differentiated to be useful for many applications.”

Additional researchers from the University of Chicago, Argonne National Laboratory, the US Army Research Laboratory, NASA, and the National Institute for Standards and Technology (NIST) contributed to the work.

Funding for the work came from the National Science Foundation, National Science Foundation Material Research Science and Engineering Center (MRSEC), a NASA Space Technology Graduate Research Opportunity, Army Research Laboratory, and NIST Center for Hierarchical Materials Design.

Source: University of Chicago