Lithium-ion batteries that contain a new non-flammable electrolyte can continue to function at high temperatures without catching fire.

Rechargeable lithium-ion batteries power phones, laptops, other personal electronics, and electric cars, and are even used to store energy generated by solar panels. But if the temperature of these batteries rises too high, they stop working and can catch fire.

That’s in part because the electrolyte inside of them, which ferries lithium ions between the two electrodes as the battery charges and discharges, is flammable.

“One of the biggest challenges in the battery industry is this safety issue, so there’s a lot of effort going into trying to make a battery electrolyte that is safe,” says Rachel Z. Huang, a graduate student at Stanford University and first author of the study in the journal Matter.

The new electrolyte’s secret? More salt.

Non-flammable electrolytes

Conventional lithium-ion battery electrolytes are made of a lithium salt dissolved in a liquid organic solvent, such as ether or carbonate. While this solvent improves battery performance by helping to move lithium ions around, it’s also a potential fire starter.

Batteries generate heat as they operate. And if there are punctures or defects in a battery, it will heat up rapidly. At temperatures above 140 degrees F, the small molecules of solvent in the electrolyte start to evaporate, transforming from liquid to gas and inflating a battery like a balloon—until the gas catches fire and the whole thing goes up in flames.

Over the past 30 years researchers have developed non-flammable electrolytes, such as polymer electrolytes, which use a polymer matrix instead of the classic salt-solvent solution to move ions around. However, these safer alternatives don’t move ions as efficiently as liquid solvents do, so their performance has not measured up to that of conventional electrolytes.

The team wanted to produce a polymer-based electrolyte that could offer both safety and performance. And Huang had an idea.

She decided to add as much as she could of a lithium salt called LiFSI to a polymer-based electrolyte designed and synthesized by Jian-Cheng Lai, a postdoctoral scholar at Stanford University and co-first author of the paper.

“I just wanted to see how much I could add and test the limit,” Huang says. Usually, less than 50% of a polymer-based electrolyte’s weight is salt. Huang bumped that number to 63%, creating one of the saltiest polymer-based electrolytes ever.

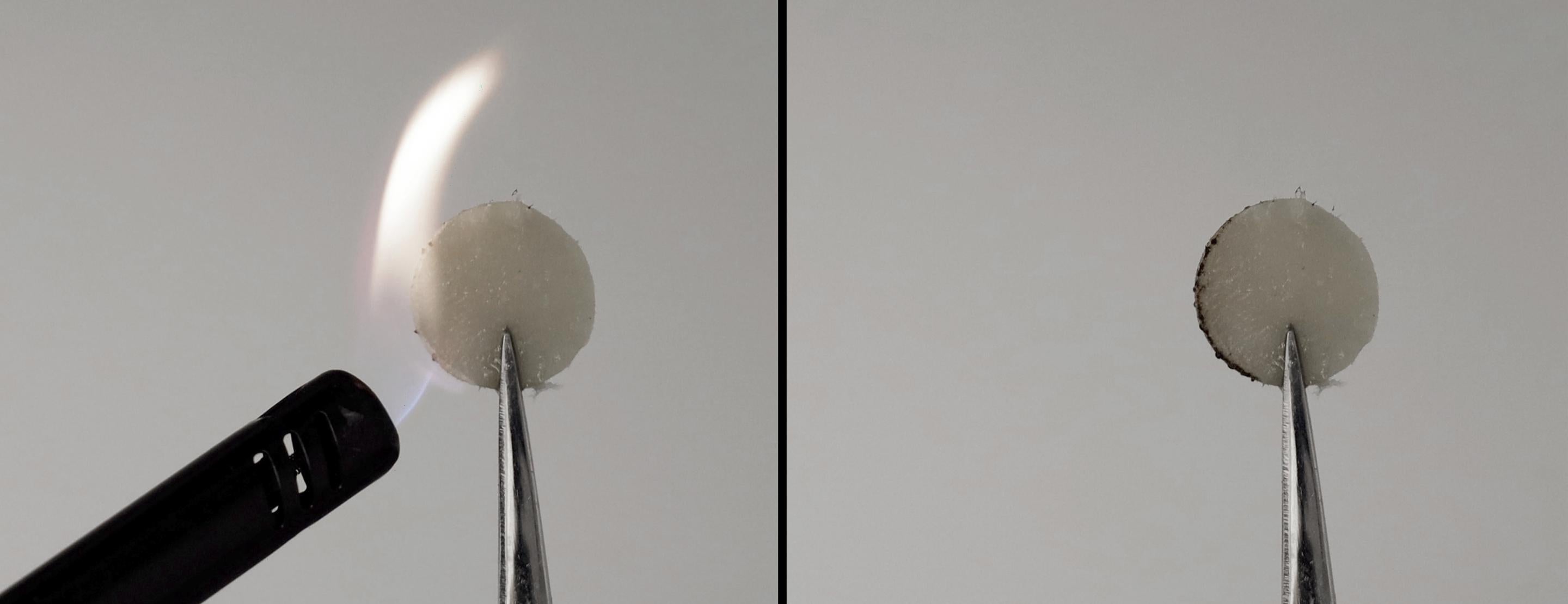

Unlike other polymer-based electrolytes, this one also contained flammable solvent molecules. However, the overall electrolyte, known as Solvent-Anchored non-Flammable Electrolyte (SAFE), proved non-flammable at high temperatures during tests in a lithium-ion battery.

SAFE works because the solvents and salt work together. The solvent molecules help conduct ions, resulting in performance comparable to that of batteries containing conventional electrolytes. But, instead of failing at high temperatures like most lithium-ion batteries, batteries containing SAFE continue to operate at temperatures between 77–212 degrees F.

Meanwhile, the ample added salts act as anchors for the solvent molecules, preventing them from evaporating and catching fire.

“This new finding points out a new way of thinking for polymer-based electrolyte design,” says Zhenan Bao, a professor at Stanford University and investigator with the Stanford Institute for Materials and Energy Sciences (SIMES) who advises Huang. “This electrolyte is important for developing future batteries that are both high energy density and safe.”

Gooey electrolytes

Polymer-based electrolytes can be solid or liquid. Importantly, the solvents and salt in SAFE plasticize its polymer matrix to make it a goo-like liquid, just like conventional electrolytes.

One benefit: A gooey electrolyte can fit into existing, commercially available lithium-ion battery parts, unlike other non-flammable electrolytes that have emerged. Solid-state ceramic electrolytes, for example, must use specially designed electrodes, making them costly to produce.

“With SAFE there’s no need to change any of the manufacturing setup,” Huang says. “Of course, if it is ever used for production there are optimizations needed for the electrolyte to fit into the production line, but the work is a lot less than any of the other systems.”

“This very exciting new battery electrolyte is compatible with the existing lithium ion-battery cell technology and would make big impacts on consumer electronics and electrical transportation,” says Yi Cui, a professor at SLAC and Stanford and a SIMES investigator who also advises Huang.

Next up: Electric cars?

If the multiple lithium-ion batteries in an electric car sit too close together, they can heat each other up, which could eventually lead to overheating and fire. But, if an electric car contains batteries filled with an electrolyte like SAFE that is stable at high temperatures, its batteries can be packed close together without worry of overheating.

In addition to mitigating fire risk, this means less space occupied by cooling systems and more space for batteries. More batteries increase the overall energy density, meaning the car could go longer between charging.

“So it’s not just a safety benefit,” says Huang. “This electrolyte could also allow you to pack in a lot more batteries.”

Time will tell what other battery-powered products could get a little SAFE-er.

The DOE’s Office of Energy Efficiency and Renewable Energy under the Battery Materials Research Program and Battery 500 Consortium funded the work.

Source: Chris Patrick for Stanford University