A new method to quickly produce fibers from carbon nanotubes is both handmade and high tech.

The method allows researchers to make short lengths of strong, conductive fibers from small samples of bulk nanotubes in about an hour.

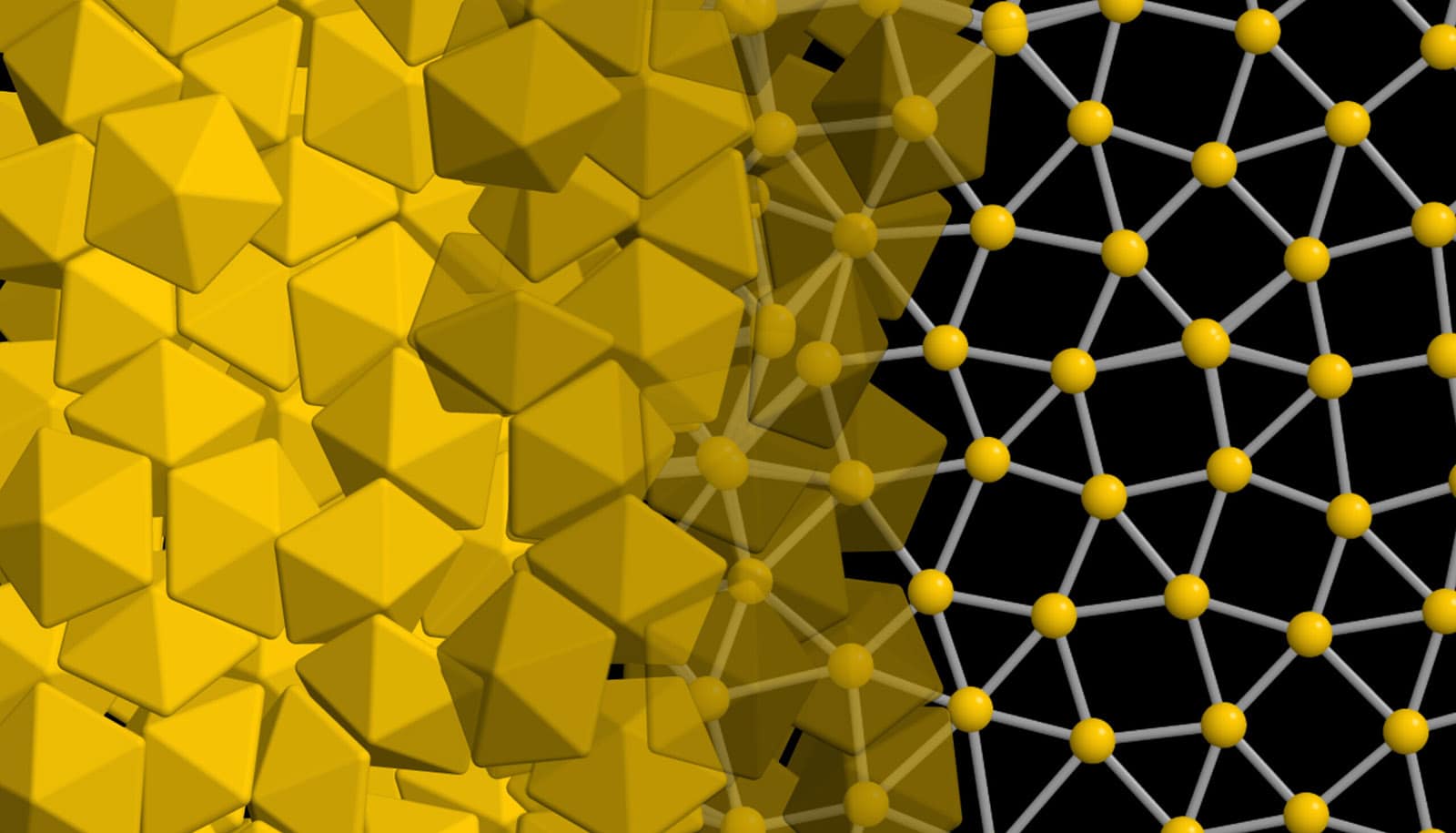

In 2013, Rice University chemist Matteo Pasquali found a way to spin full spools of thread-like nanotube fibers for aerospace, automotive, medical, and smart-clothing applications. The fibers look like cotton thread but perform like metal wires and carbon fibers.

It can take grams of material and weeks of effort to optimize the process of spinning continuous fibers, but the new method cuts that down to size, even if it does require a bit of hands-on processing.

“It speeds things up and allows us to explore nanotubes that are only available in small quantities.”

Pasquali and lead author and graduate student Robby Headrick report in Advanced Materials that aligning and twisting the hair-like fibers is fairly simple.

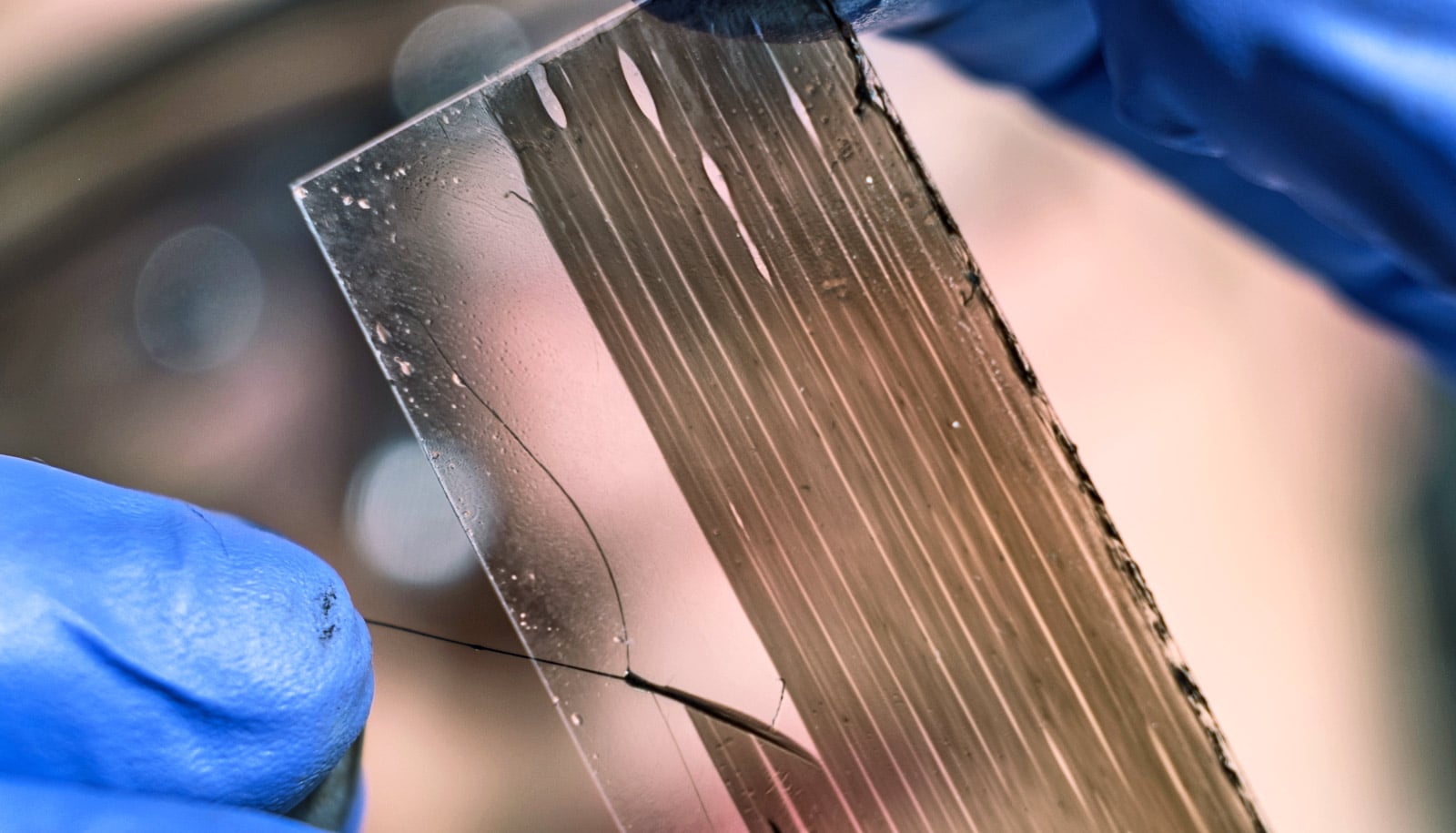

First, Headrick makes films. After dissolving a small amount of nanotubes in acid, he places the solution between two glass slides. Moving them quickly past each other applies shear force that prompts the billions of nanotubes within the solution to line up. Once the resulting films are deposited onto the glass, he peels off sections and rolls them up into fibers.

“The film is in a gel state when I peel it, which is important to get a fully densified fiber,” Headrick says. “You twist it when it’s wet throughout the cross section of the structure, and when you dry it, the capillary pressure densifies it.”

Headrick was dissatisfied with the reproducibility of his initial experiments and discussed the procedure with his father, Robert, an amateur woodworker. The elder Headrick quickly came up with a simple device to support the slides and control the shearing process.

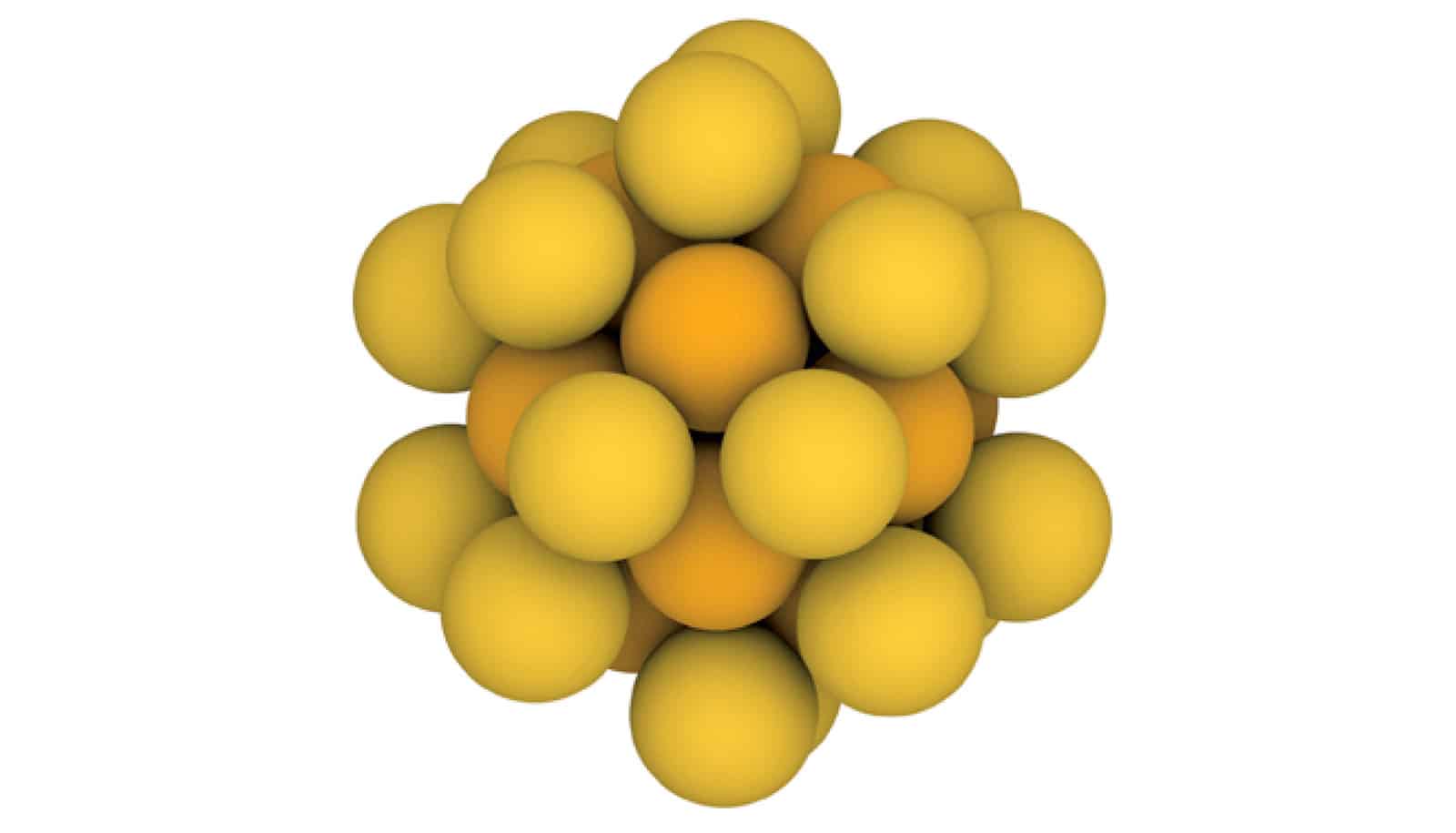

The dried nanotube fibers are about 7 centimeters long; the electrical performance is equivalent to long fibers created by the original spinning method but even more dense with a tensile strength up to 3.5 gigapascals (GPa), better than spun fibers. The researchers expect that nanotubes 50,000 to 70,000 times longer than they are wide will produce fibers of 35 to 40 GPa, about the strength of an individual carbon nanotube.

“We can process all kinds of nanotubes the exact same way so we get optimal fiber structures and properties,” Headrick says. “It speeds things up and allows us to explore nanotubes that are only available in small quantities.”

Nano fibers get their structure from DNA ‘origami’

The process reproduces the high nanotube alignment and high packing density typical of fibers produced via spinning, but at a size sufficient for strength and conductivity tests, says Pasquali, professor of chemical and biomolecular engineering, of materials science and nanoengineering, and of chemistry.

“We now use this as a quick lab test to assess new materials and to create target properties for the large-scale method,” Pasquali says. “We’ll know in advance what the material can deliver, whereas before, we could only infer it. This could be especially important for carbon nanotube producers who want to change their reactor conditions to give them quick feedback or for quality control, as well as for testing samples that have been sorted by metallic versus semiconductor type or even helicity.”

Coauthors of the paper are from DexMat Inc.; the Universal Technology Corp. and Air Force Research Laboratory in Dayton, Ohio; and Technion-Israel Institute of Technology.

The Air Force Office of Scientific Research, the Robert A. Welch Foundation, the United States-Israel Binational Science Foundation, and a NASA Space Technology Research Fellowship supported the research.

Source: Rice University