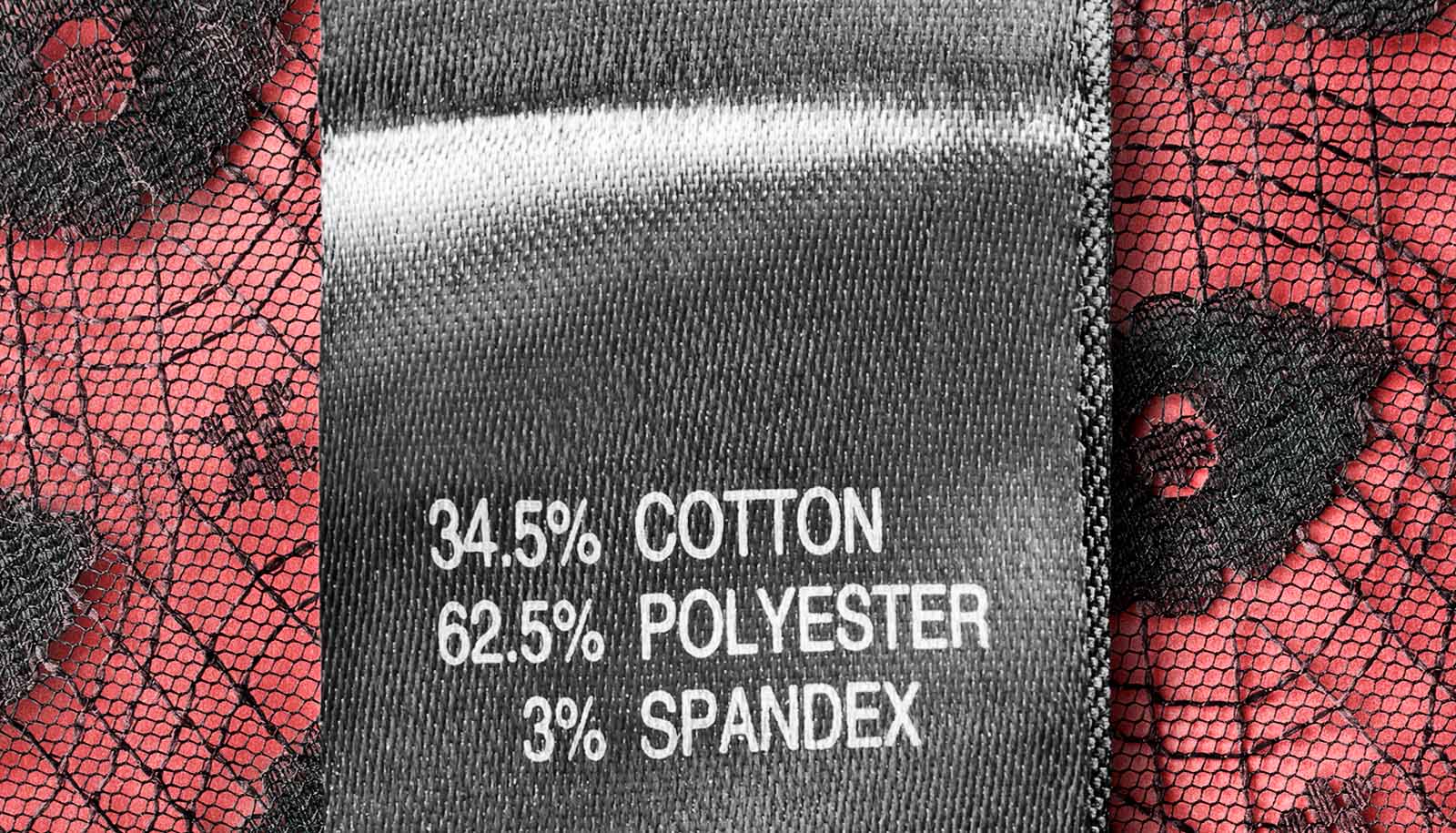

Researchers report using enzymes to separate blended cotton and polyester fabric, an advance that could lead to reduced textile waste.

Ultimately, they hope their findings will lead to a more efficient way to recycle the fabric’s component materials, thereby reducing textile waste.

However, their work shows that the process needs more steps if the blended fabric was dyed or treated with chemicals that increase wrinkle resistance.

“We can separate all of the cotton out of a cotton-polyester blend, meaning now we have clean polyester that can be recycled,” says corresponding author of the study Sonja Salmon, associate professor of textile engineering, chemistry, and science at North Carolina State University. “In a landfill, the polyester is not going to degrade, and the cotton might take several months or more to break down. Using our method, we can separate the cotton from polyester in less than 48 hours.”

According to the US Environmental Protection Agency, people throw approximately 11 million tons of textile waste into US landfills each year. The researchers wanted to develop a method of separating the cotton from the polyester so each component material could be recycled.

In the study in the journal Resources, Environment and Sustainability, researchers used a “cocktail” of enzymes in a mildly acidic solution to chop up cellulose in cotton. Cellulose is the material that gives structure to plants’ cell walls. The idea is to chop up the cellulose so it will “fall out” out of the blended woven structure, leaving some tiny cotton fiber fragments remaining, along with glucose. Glucose is the biodegradable byproduct of degraded cellulose. Then, their process involves washing away the glucose and filtering out the cotton fiber fragments, leaving clean polyester.

“This is a mild process—the treatment is slightly acidic, like using vinegar,” Salmon says. “We also ran it at 50 degrees Celsius, which is like the temperature of a hot washing machine.

“It’s quite promising that we can separate the polyester to a clean level,” Salmon adds. “We still have some more work to do to characterize the polyester’s properties, but we think they will be very good because the conditions are so mild. We’re just adding enzymes that ignore the polyester.”

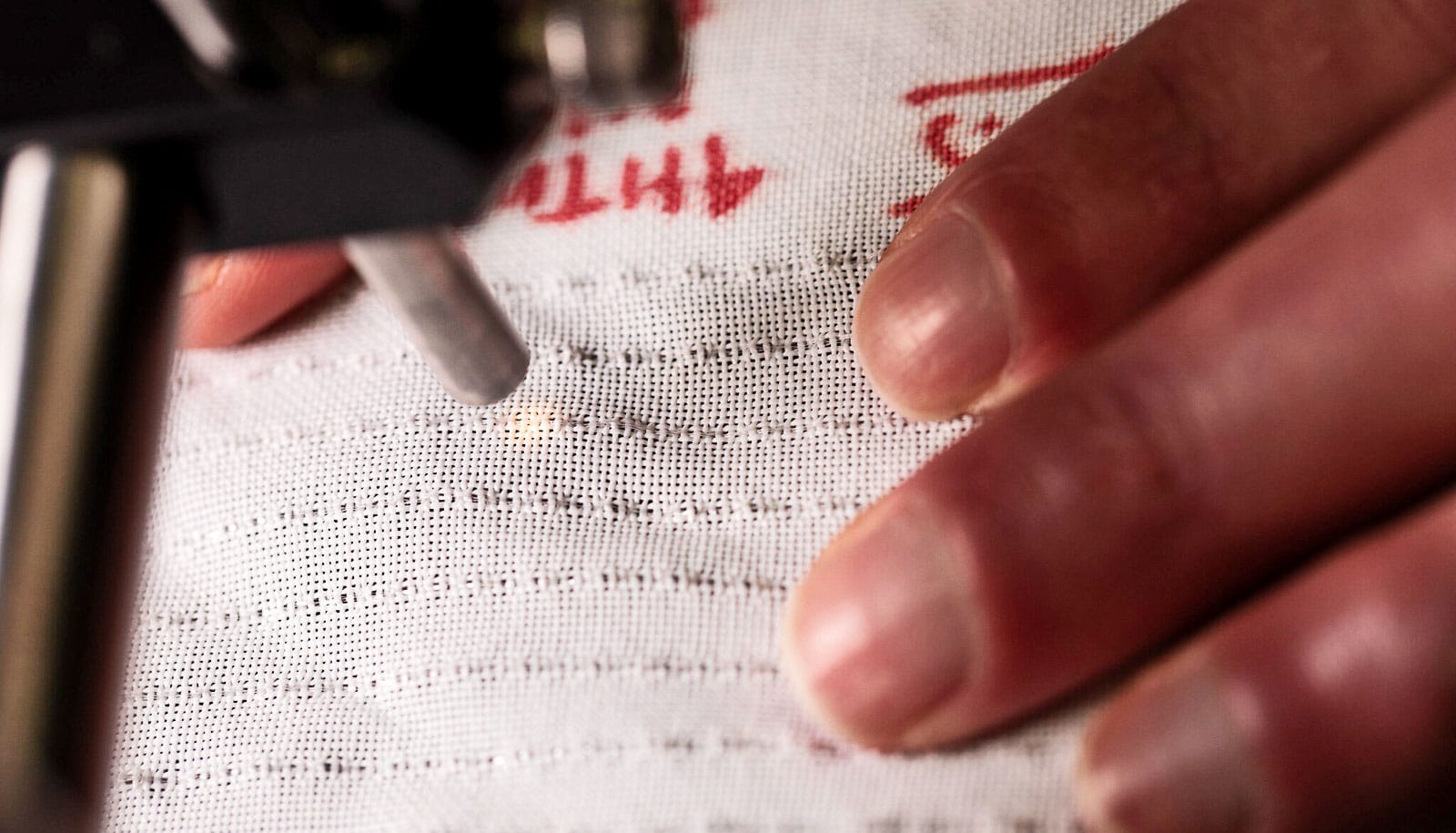

They compared degradation of 100% cotton fabric to degradation of cotton and polyester blends, and also tested fabric that was dyed with red and blue reactive dyes and treated with durable press chemicals. In order to break down the dyed materials, the researchers had to increase the amount of time and enzymes used. For fabrics treated with durable press chemicals, they had to use a chemical pre-treatment before adding the enzymes.

“The dye that you choose has a big impact on the potential degradation of the fabric,” says lead author Jeannie Egan, a graduate student at NC State. “Also, we found the biggest obstacle so far is the wrinkle-resistant finish. The chemistry behind that creates a significant block for the enzyme to access the cellulose. Without pre-treating it, we achieved less than 10% degradation, but after, with two enzyme doses, we were able to fully degrade it, which was a really exciting result.”

The researchers say the polyester could be recycled, and the slurry of cotton fragments could be valuable as an additive for paper or useful addition to composite materials. They’re also investigating whether the glucose could be used to make biofuels.

“The slurry is made of residual cotton fragments that resist a very powerful enzymatic degradation,” Salmon says. “It has potential value as a strengthening agent. For the glucose syrup, we’re collaborating on a project to see if we can feed it into an anaerobic digester to make biofuel. We’d be taking waste and turning it into bioenergy, which would be much better than throwing it into a landfill.”

Funding came from the Environmental Research and Education Foundation; Kaneka Corporation; and the university’s department of textile engineering, chemistry, and science.

Source: NC State