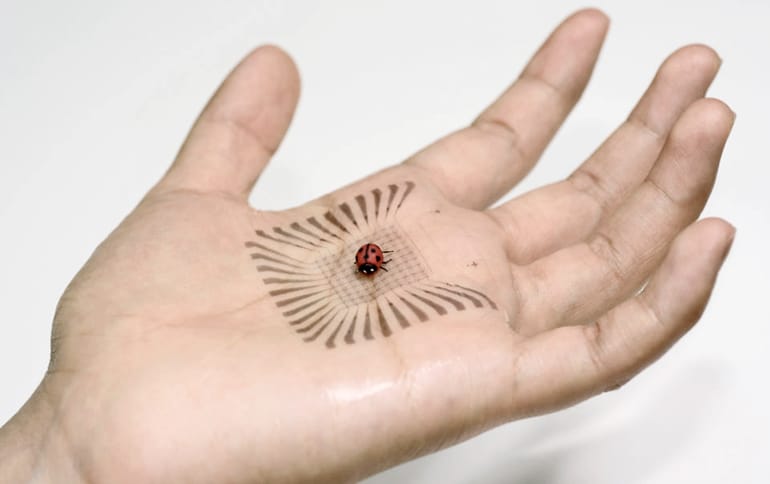

New research sets the stage for an evolution in electronics by taking the concept of “artificial skin” to the next level. The work demonstrates not only a stretchable circuitry that can feel the touch of a ladybug, but also a manufacturing process to mass-produce this circuitry.

Restoring some semblance of touch to people who use prosthetic limbs has been a driving force behind Stanford University chemical engineer Zhenan Bao’s decades-long quest to create stretchable, electronically sensitive synthetic materials. Such a breakthrough could one day serve as skin-like coverings for prosthetics. But in the near term, this same technology could become the foundation for the evolution of new genre of flexible electronics very different from the rigid smartphones in our back pockets.

“Research into synthetic skin and flexible electronics has come a long way, but until now no one had demonstrated a process to reliably manufacture stretchable circuits,” says Bao, whose findings appear in Nature.

Bao’s hope is that manufacturers might one day be able to make sheets of polymer-based electronics embedded with a broad variety of sensors, and eventually connect these flexible, multipurpose circuits with a person’s nervous system. Such a product would be analogous to the vastly more complex biochemical sensory network and surface protection “material” that we call human skin, which can not only sense touch, but also temperature and other phenomena.

A 2-inch square of the material contains more than 6,000 individual signal-processing devices that act like synthetic nerve endings.

But long before artificial skin becomes possible, the processes reported in the Nature paper will enable the creation of foldable, stretchable touchscreens, electronic clothing, or skin-like patches for medical applications.

Bao says their production process involves several layers of new-age polymers, some that provide the material’s elasticity and others with intricately patterned electronic meshes. Still, others serve as insulators to isolate the electronically sensitive material. One step in the production process involves the use of an inkjet printer to, in essence, paint on certain layers.

“We’ve engineered all of these layers and their active elements to work together flawlessly,” says postdoctoral scholar Sihong Wang, co-lead author of the paper.

The team has successfully fashioned its material in squares about two inches on a side containing more than 6,000 individual signal-processing devices that act like synthetic nerve endings. All this is encapsulated in a waterproof protective layer.

The prototype can be stretched to double its original dimensions—and back again—all the while maintaining its ability to conduct electricity without cracks, delamination, or wrinkles. To test durability, the team stretched a sample more than one thousand times without significant damage or loss of sensitivity. The real test came when the researchers adhered their sample to a human hand.

“It works great, even on irregularly shaped surfaces,” says postdoctoral scholar Jie Xu, and the paper’s other co-lead author.

‘Skin’ sensor gives robots a better sense of touch

Perhaps most promising of all, the fabrication process described in this paper could become a platform for evaluating other stretchable electronic materials developed by other researchers that could one day begin to replace today’s rigid electronics.

Bao says much work lies ahead before these new materials and processes are as ubiquitous and capable as rigid silicon circuitry. First up, she says, her team must improve the electronic speed and performance of their prototype, but this is a promising step.

Samsung Electronics, the National Science Foundation Graduate Research Fellowship Program, and NETEP and MOTIE of the Republic of Korea supported the work.

Source: Stanford University