Researchers have created a new kind of artificial cartilage using Kevlar, the same material in bulletproof body armor.

The unparalleled liquid strength of cartilage, which is about 80 percent water, withstands some of the toughest forces on our bodies. Synthetic materials couldn’t match it—until researchers created the new “Kevlartilage.”

“We know that we consist mostly of water—all life does—and yet our bodies have a lot of structural stability,” says Nicholas Kotov, a professor of engineering at the University of Michigan, who led the study. “Understanding cartilage is understanding how life forms can combine properties that are sometimes unthinkable together.”

Many people with joint injuries would benefit from a good replacement for cartilage, such as the 850,000 patients in the US who undergo surgeries removing or replacing cartilage in the knee.

While other varieties of artificial cartilage are already undergoing clinical trials, these materials fall into two camps that choose between cartilage attributes, unable to achieve that unlikely combination of strength and water content.

The other synthetic materials that mimic the physical properties of cartilage don’t contain enough water to transport the nutrients that cells need to thrive, Kotov says.

Meanwhile, hydrogels—which incorporate water into a network of long, flexible molecules—can be designed with enough water to support the growth of the chondrocytes cells that build up natural cartilage. Yet those hydrogels aren’t especially strong. They tear under strains a fraction of what cartilage can handle.

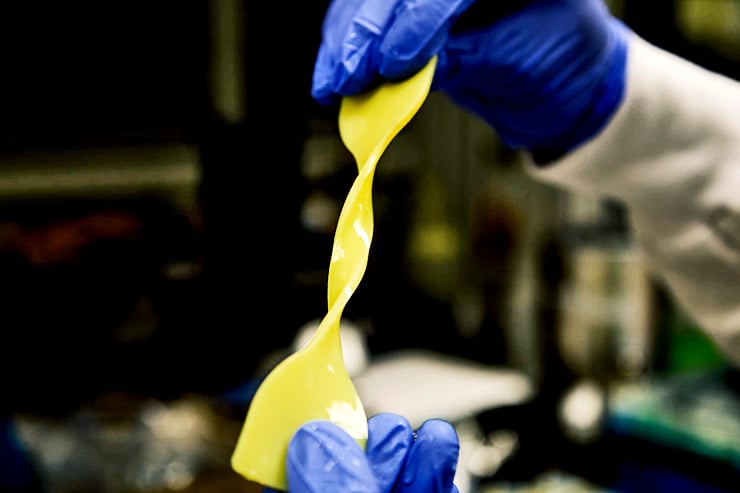

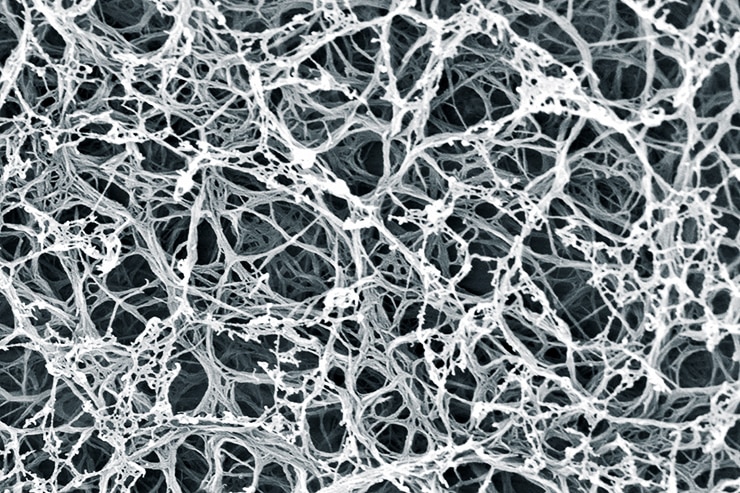

The new Kevlar-based hydrogel recreates the magic of cartilage by combining a network of tough nanofibers from Kevlar—the “aramid” fibers best known for making bulletproof vests—with a material commonly used in hydrogel cartilage replacements, called polyvinyl alcohol, or PVA.

In natural cartilage, the network of proteins and other biomolecules gets its strength by resisting the flow of water among its chambers. The pressure from the water reconfigures the network, enabling it to deform without breaking. The process releases water, and the network recovers by absorbing water later.

This mechanism enables high impact joints, such as knees, to stand up to punishing forces. Running repeatedly pounds the cartilage between the bones, forcing water out and making the cartilage more pliable as a result. Then, when the runner rests, the cartilage absorbs water so that it provides strong resistance to compression again.

The synthetic cartilage boasts the same mechanism, releasing water under stress and later recovering by absorbing water like a sponge. The aramid nanofibers build the framework of the material, while the PVA traps water inside the network when the material stretches or compresses. Even versions of the material that were 92 percent water were comparable in strength to cartilage, with the 70-percent version achieving the resilience of rubber.

As the aramid nanofibers and PVA don’t harm adjacent cells, Kotov anticipates that this synthetic cartilage may be a suitable implant for some situations, such as the deeper parts of the knee. He also wonders whether chondrocytes might be able to take up residence inside the synthetic network to produce a hybrid cartilage.

But his potential applications are not limited to cartilage. He suspects that similar networks, with different proportions of aramid nanofibers, PVA and water, may be able to stand in for other soft tissues.

“We have a lot of membranes in the body that require the same properties. I would like to evaluate the space,” Kotov says. “I will talk to doctors about where the acute need is and where this intersection of the properties will allow us to make best headway and biggest impact.”

Lab-grown cartilage mimics the real thing

The study appears in Advanced Materials.

The National Science Foundation, with additional funding from the Department of Defense, supported the study. The university is seeking patent protection and partners to bring the technology to market.

Source: University of Michigan