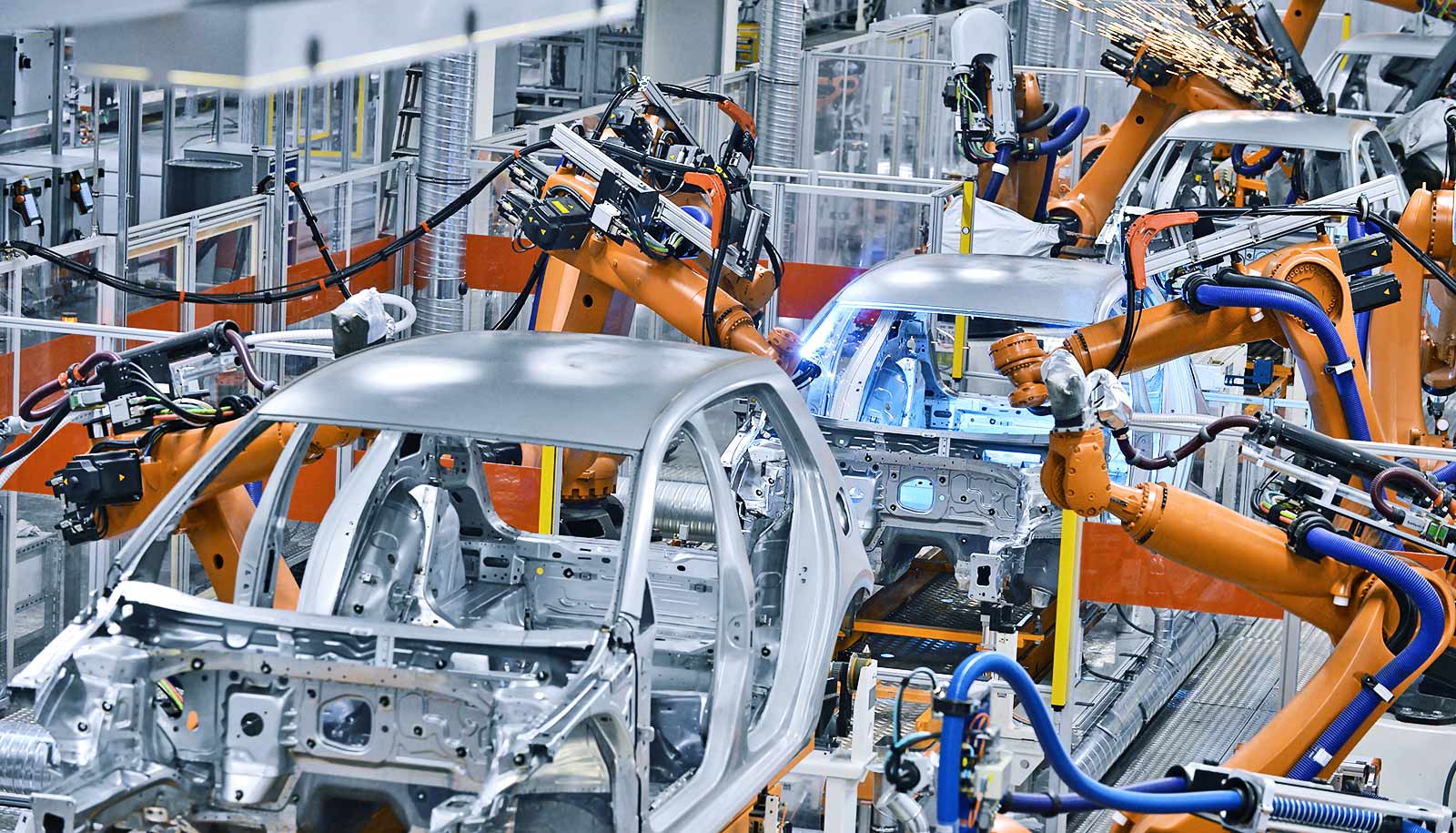

A new method makes it possible to create high-strength, lightweight steel on an industrial scale, potentially making way for its use in vehicles.

Researchers have developed a new processing route which allows low density steel-based alloys to be produced with maximum strength, while remaining durable and flexible—something that has been largely impossible until now.

Vehicles made of stronger and lighter materials are safer for drivers, emit less CO2, and consume less fuel—and more malleable steels would allow manufacturers to form car parts into streamlined shapes.

“Alloys with higher strength and ductility could alleviate some of these concerns by reducing weight and improving energy efficiency. Lightweight steels are one of the candidates to address these concerns,” says Alireza Rahnama, a research fellow at the Warwick Manufacturing Group at the University of Warwick.

Rahnama and colleagues tested two lightweight steels—Fe-15Mn-10Al-0.8C-5Ni and Fe-15Mn-10Al-0.8C—for their potential to achieve maximum strength and ductility.

During production, two brittle phases can occur in these steels: kappa-carbide (k-carbide) and B2 intermetallic—which make the steels hard but limits their ductility, so they are difficult to roll.

Through simulation and then experimentation, researchers found that at certain high annealing temperatures, these brittle phases can become much more controllable, allowing the steels to retain their ductility.

Between 900°C to 1200° C, the k-carbide phase can be removed from production, and the B2 intermetallic brittle phase can become manageable, as opposed to a coarser product which forms at lower temperatures.

Current processes for strengthening lightweight steels make them less flexible—and therefore less marketable—but the new research could make this a problem of the past.

Twisted steel stays strong and pliable

The research appears in Acta Materialia.

The Warwick Manufacturing Group center High Value Manufacturing (HVM) Catapult funded this project.

Source: University of Warwick